Routing Fingerboard Inlays

Cut precise, clean, and tight-fitting inlay pockets

Our custom router base works with a variety of template designs and scales that cover the most popular fingerboard inlay styles. These tools were developed and tested in our StewMac shop, with the design and inspiration from our friends at Texas Toast Guitars.

What You'll Need

- Inlay Jig Plunge Router Base (or Inlay Plate to retrofit your Plunge Router Base)

- Dremel or similar rotary tool

- 1/16" Router Bit (provided with the Inlay Jig)

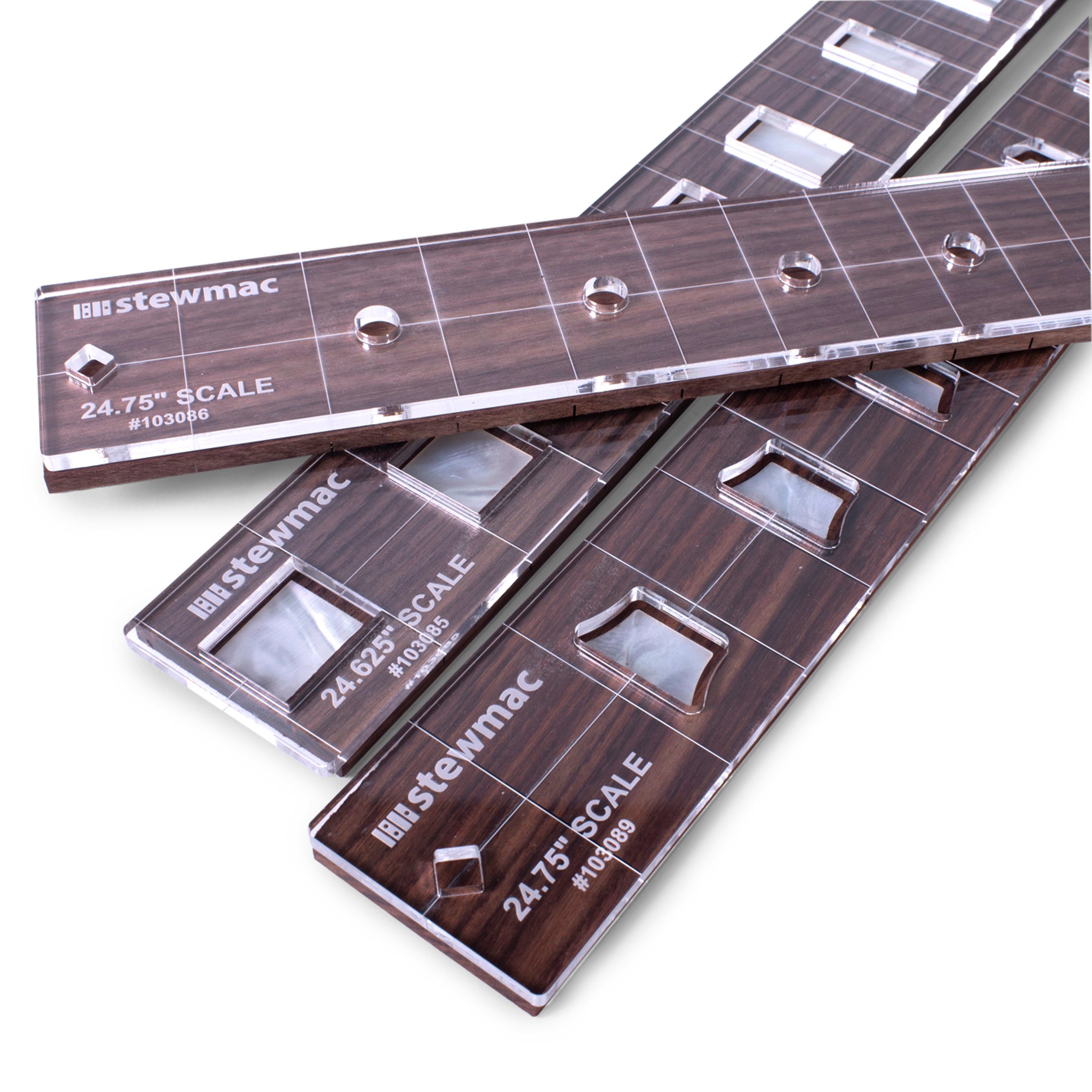

- Fingerboard Inlay Routing Template: a variety of inlay shapes and scale lengths are available at stewmac.com

- Fingerboard: unradiused (flat) and with fret slots

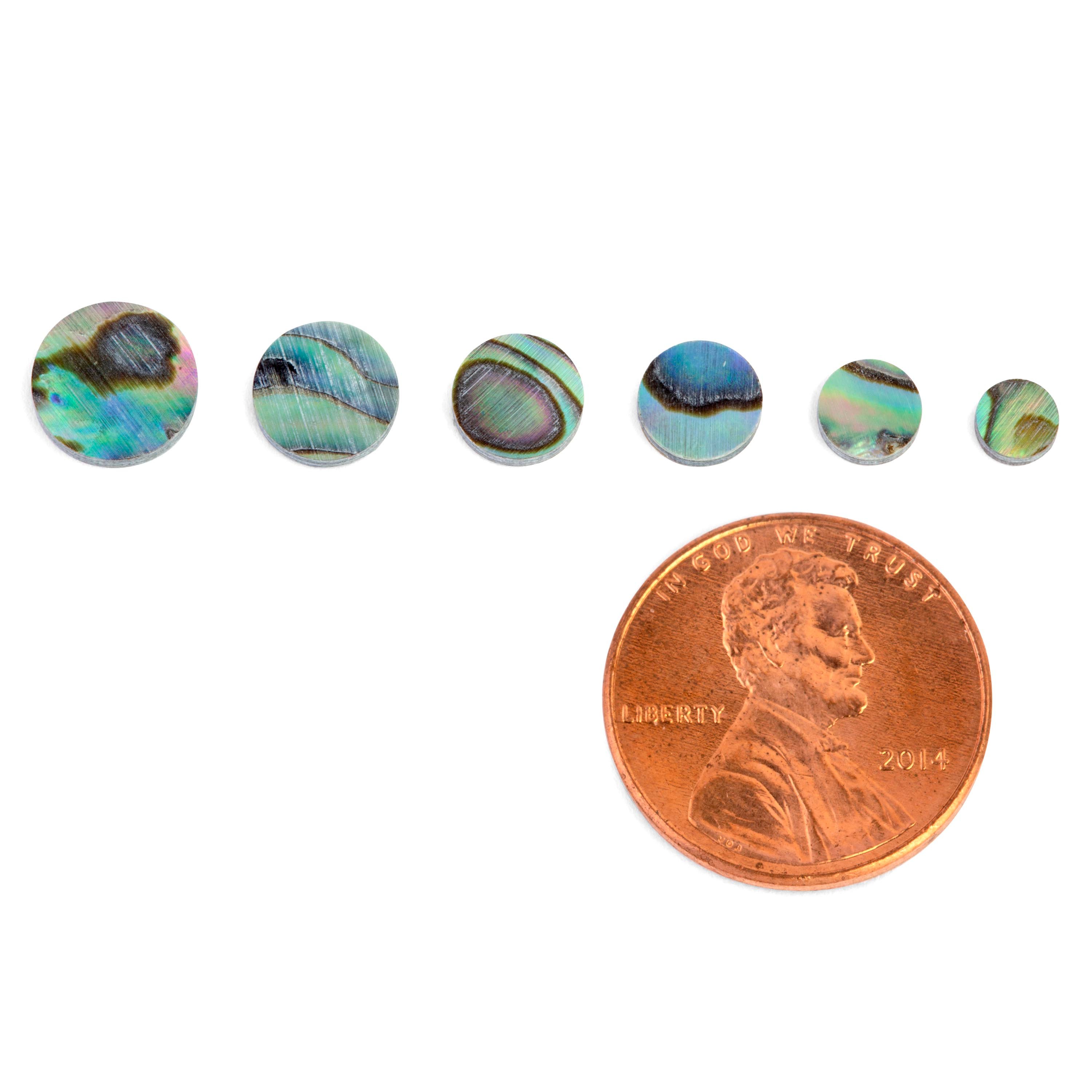

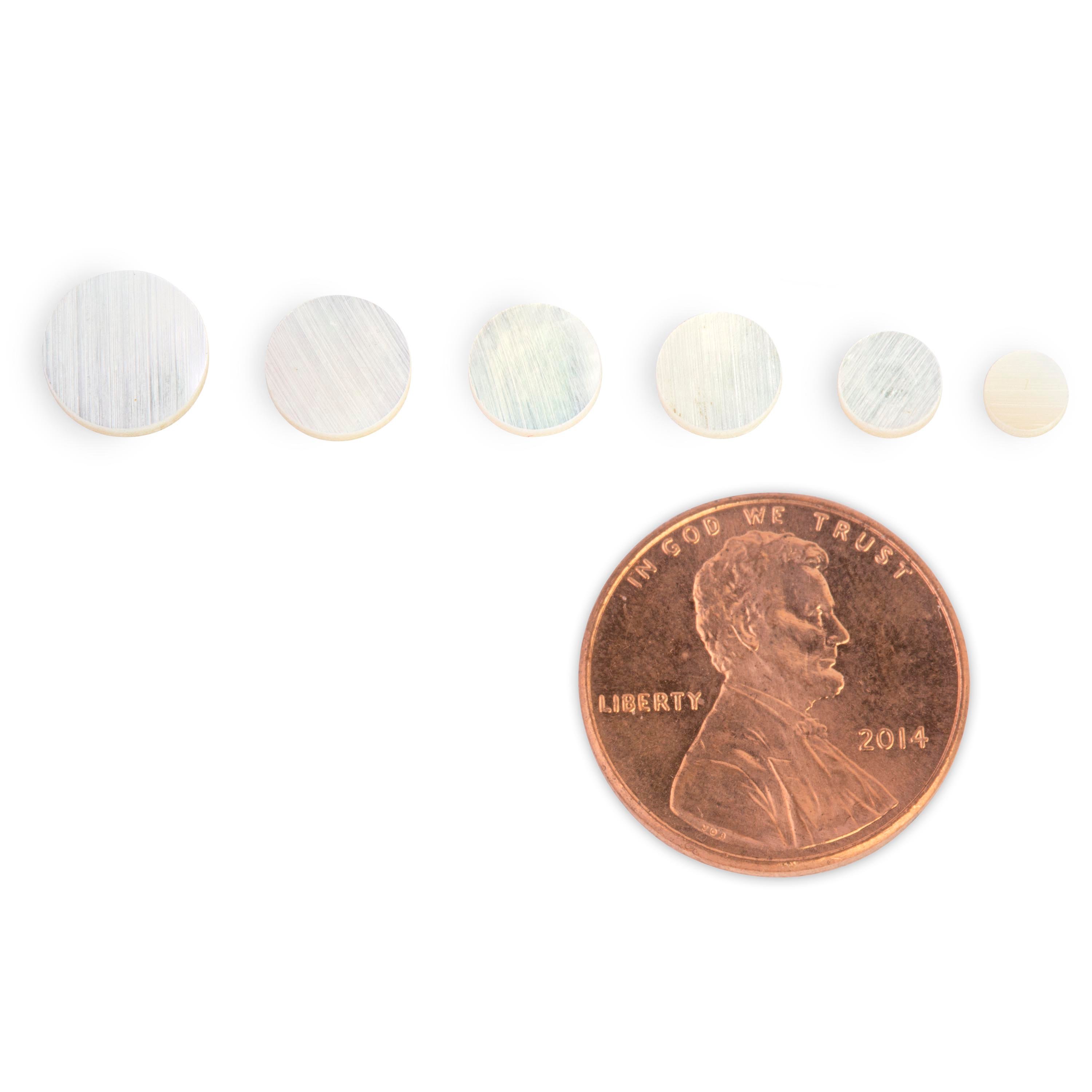

- Inlay material

- Straightedge

- Double-stick tape

- White pencil

- StewMac Super Glue #30 Thick (or other CA glue)

- Vacuum

- Micro chisel

StewMac Inlay Jig Plunge Router Base #103758

This router base comes complete with a clear acrylic baseplate designed to work with our Fingerboard Inlay Routing Templates.

Ball grips + plunge lock: The ball grips used to guide the tool also control the plunge lock. Loosen the grips to plunge, then tighten to lock the unit in place.

Primary depth stop adjustment: Some bits are longer than others, so the amount of downward plunge needed can vary. Use the primary adjustment knob on the back of the unit to get you in the ballpark, then use the micro adjustment to dial in your exact depth. This adjustment has approximately 1/2" of plunge depth.

Micro depth stop adjustment: Set the micro depth stop adjustment to be in the middle of its plunge for adjustment in either direction. Each full turn of the knurled knob gives around 1/32" of adjustment.

LED light: The rechargeable LED light cycles through three brightness settings. The included micro USB charging cable can be used with any USB power adapter capable of handling 500 mAh.

Air nozzle: Built-in nozzle for attaching a mini air pump to continuously blow away the dust while routing.

Fits rotary tools with a 3/4-12 threaded plastic collar:

- Most Dremel models made since 1986

- Black & Decker Wizard™ and RTX™

- Foredom Custom Handpiece from StewMac

Inlay Plate Retrofit #103078

The StewMac Inlay Plate can be purchased separately and will retrofit to the original StewMac Plunge Router Base (#5806). Here's how to swap the solid base with the new acrylic baseplate:

- Unscrew the depth stop from the underside of your Plunge Router Base.

- Attach the depth stop to the Inlay Plate with one of the provided mounting screws. Note the brass bearing sleeve should protrude from the bottom (it will not sit flat).

- Remove the stock base from the Plunge Router Base.

- Using the provided screws, install the Inlay Plate to the Plunge Router Base, leaving the screws loose for now.

Inlay Jig Router Base Setup

Align the tool with the base

Remove the threaded plastic collar from your rotary tool and screw the router base onto the tool until snug.

Set the alignment using the provided indexing pin: Chuck the narrow end of the pin into the rotary tool's collet, and use finger pressure to tighten.

Unlock the primary depth stop adjustment and rotate the ball grips counterclockwise to loosen the base.

Plunge the base so the indexing pin runs through the bearing sleeve in the baseplate. Lock the base in place by rotating the ball grips clockwise.

|

Inlay Plate Retrofit: If you retrofit your own base, now is the time to tighten the bottom screws to lock in the alignment. |

|

Now you can remove the indexing pin and chuck a 1/16" downcut bit in the rotary tool. Note: While an upcut bit could work, you run the risk of compacting dust under the inlay plate. A downcut bit will push the dust into the pocket, keeping the bit clear.

Set the plunge depth stop

Place the inlay jig on a fingerboard template with the brass collet inside a pocket shape—this is just for setting the plunge depth, so the template can be on a table.

Loosen the ball grips to lower the bit so that it just touches the fingerboard (or table) through one of the template pockets. Lock the position by tightening the ball grips.

Setting the plunge depth with the jig and templates can be done on any flat surface or fingerboard.

Set the micro depth stop

Use the inlay material to reset the micro depth stop. You want a final routing depth that leaves inlay flush with the top of the fingerboard or just proud of the surface. If it sits too proud, you may sand through the inlay when shaping your fingerboard radius.

Fingerboard Inlay Template Setup

Starting with a flat, slotted fingerboard, mark the centerline using a straightedge. We used a white pencil on rosewood.

StewMac Fingerboard Inlay Templates feature a centerline and fret slot lines to help with alignment. Be sure your fingerboard's fret scale matches the scale listed on the template. Orient the appropriately sized template to line up with your fingerboard.

Use double-stick tape to secure the template to the board. And again, use double-stick tape to secure the fingerboard to a sturdy work surface.

Routing Inlay Pockets

Double-check and secure your depth stop settings. Place the rotary tool on the template, and turn on the power. Lower the bit so the bearing sleeve rides along the inside of the template hole.

Rout the perimeter of the first pocket and vacuum the dust. Remove sawdust from your bit frequently, as buildup can prevent the bit from cutting the tight corners of the inlay’s shape. Repeat for the remaining pockets. Save some of the sawdust for use later.

Rout out the waste in the pocket center using small clockwise strokes, moving back and forth over the cavity until clean. Vacuum often for a better view of the work.

Routing tips

- Run the bit between 20,000-30,000 rpm.

- Clean your bit frequently.

- Vacuum sawdust frequently.

- Pay close attention to the corners to make sure they are clear.

- Save some sawdust to fill any gaps you may have.

- Take your time.

Installing Inlay

After all pockets are routed, remove the template and clean up debris and fuzz using a sharp chisel.

Squeeze several drops of thick super glue into one pocket at a time before installing the appropriate size inlay shape.

If you have any gaps between the pocket and inlay, mix the sawdust you saved earlier with a few drops of the glue. Then work this slurry into the gaps.

Radius the fretboard once the glue is dry.

Download PDF