How to Ship a Guitar Safely

Shipping a guitar doesn’t have to feel risky. With the right prep, packing sequence, and materials, you can protect the neck, headstock, and finish so your instrument shows up ready to play. Below is a practical, step-by-step guide—followed by an easier (and faster) option using StewMac’s purpose-built Guitar Shipping Systems.

What You’ll Need

Essential supplies

- Snug-fitting hard case (or a purpose-built cradle if shipping without a case)

- Sturdy guitar shipping box

- Bubble wrap

- Kraft/packing paper (ink-free)

- High-quality packing tape

- Elastic bands to keep padding in place

Avoid

- Weak tapes (masking/duct)

- Old or damaged boxes

- Newspaper/inked paper that can stain

- Packing peanuts as primary padding (they settle and don’t protect)

Pre-Ship Prep

Clean, Document, and Secure

Wipe the guitar clean, then photograph body, neck, headstock, and hardware; photos are crucial if you need to file a claim. Remove or secure anything that can rattle or scratch: trem arm, strap buttons/strap, switch tips, loose case-pocket items (capos/picks), and batteries for onboard electronics. For vintage instruments, consider removing fragile toggles or end pins.

The String-Tension Debate (and a Safe Middle Ground)

Experts disagree: some shippers/retailers suggest loosening strings; some makers (e.g., Larrivée) prefer full tension. A conservative middle ground is to slightly loosen the strings—reducing tension without going totally slack—to minimize both neck stress and headstock vulnerability.

Identify Vulnerable Areas

Immobilize the headstock area, neck joint, and any body contact gaps inside the case. For angled headstocks (e.g., many Gibson-style guitars), place crumpled paper around—not over—the headstock and don’t overstuff. Fill the heel gap so the neck can’t lever in transit, and pad body voids so the guitar can’t shift.

How to Pack a Guitar (with a Case)

1) Immobilize the Neck and Headstock

Nestle crumpled paper around the headstock and under the neck where the case leaves room; the guitar should feel “cast in place,” not squeezed. For bolt-on necks, don’t create new stress at the joint—support, don’t clamp.

2) Protect the Fretboard and Hardware

Slide a long strip of kraft paper between strings and frets to avoid imprints. Pad movable hardware—floating bridges, trapeze tails—so nothing scuffs the top. If your case has interior slack near bridge/tailpiece, fill it.

3) Box It Right

Use a box with several inches of clearance on all sides of the case. Build a cushioned base layer, center the case, then fill every void. Do the gentle shake test—if you feel or hear movement, add padding until it’s silent.

4) Seal, Label, and (Quietly) Mark

Tape all seams and protect the label with clear tape. Use “Fragile/This Way Up,” but avoid labeling “Guitar/Musical Instrument” to deter theft.

5) Ship Smart

Insure for full replacement value (standard coverage is often inadequate). Ship early in the week to avoid weekend warehousing and reduce temperature exposure; ask the recipient to inspect the box and guitar on arrival and document issues immediately.

Special Notes by Instrument Type

Tremolo/Floating-Bridge Electrics

Loosen a locking nut (if applicable) and stabilize the trem (springs/bridge) to prevent movement. Add barrier padding between hardware and finish.

Acoustic Guitars

Hollow bodies are more sensitive to humidity/temperature swings. Remove loose soundhole accessories, pad interior allowances if your case has them, and be extra careful at the neck joint and headstock.

Bass Guitars

Longer scale and heavier weight create more leverage on the neck—prioritize neck immobilization and consider pro packing for high-end basses.

Common Mistakes to Avoid

- Shipping without a hard case (or proper non-case cradle)

- Using old/damaged boxes or foam peanuts as primary padding

- Leaving room for the case to rattle inside the box

- Skipping adequate insurance on valuable instruments

- Over-tightening wraps that create pressure points

Make It Easy: StewMac Guitar Shipping Systems

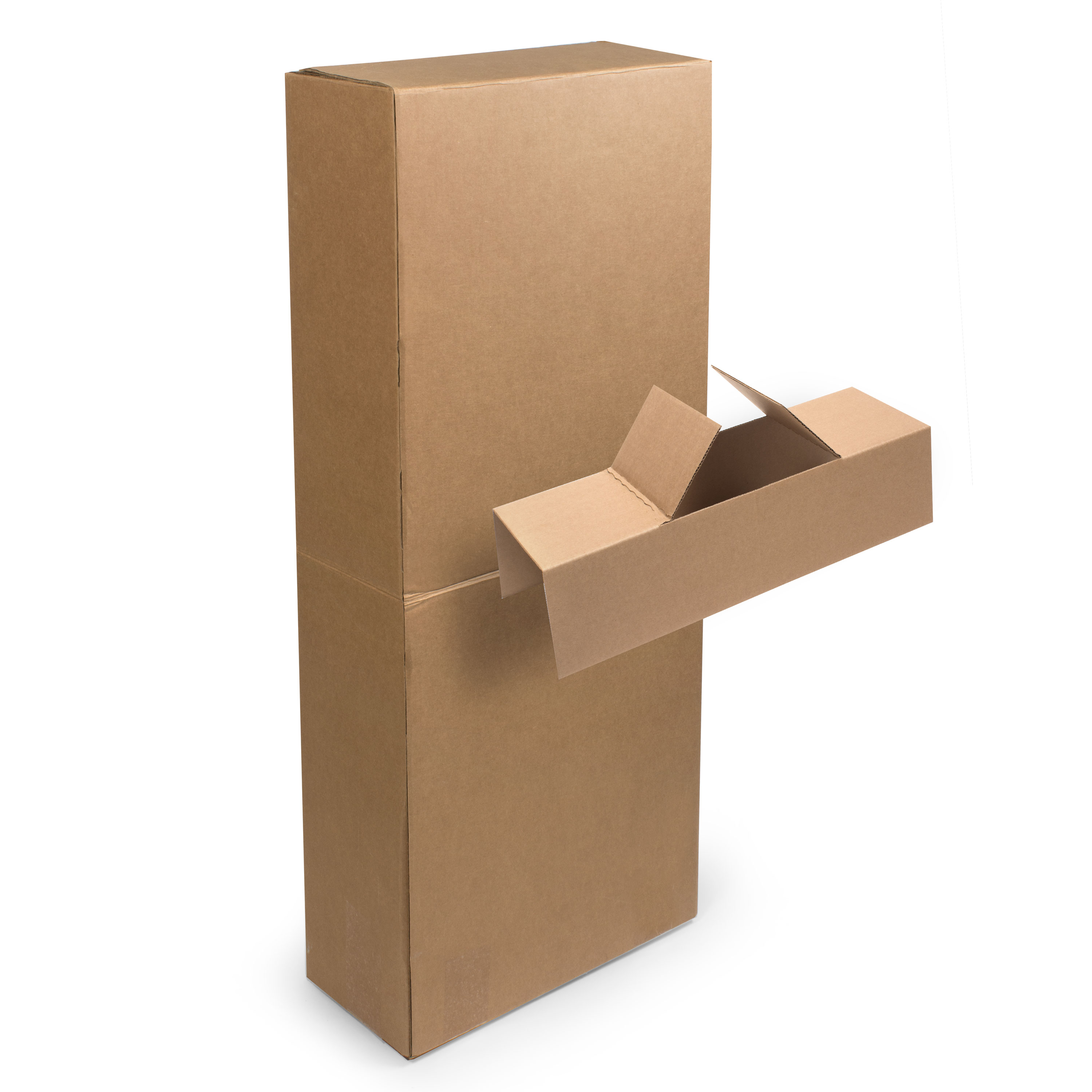

If you’d rather not DIY the padding geometry, StewMac’s Guitar Shipping Systems (with Aeris inflatable components) streamline the whole job—engineered supports cradle the body/neck, lock out movement, and compress the contents when you tape the box shut. Kits are available for electric (with case), acoustic (with case), and bare guitar (no case).

What’s in the Kits

- Electric with Case: shipping box, center box reinforcement beam, inflatable top hat, and inflatable bottom wrap (or bottom end caps for rectangular cases).

- Acoustic with Case: shipping box, center beam, inflatable top hat, inflatable bottom end cap—purpose-shaped for acoustic cases.

- Acoustic or Electric Guitars with No Case: shipping box, fabric guitar bag, inflatable guitar vest, center reinforcement beam, and neck stabilizer insert.

Quick-Start Overviews

Electric Guitar with Case

- Prepare & Inflate: Unfold/tape the box; inflate one top hat + one bottom wrap.

- Bottom-up fill: Lay the bottom wrap across the opening, lower the case so the wrap hugs the lower portion/sides.

- Lock & Top: Drop in the center beam through its opening so it rests on the case shoulders; insert the top hat; tape closed (a slight top-hat protrusion is by design to compress contents).

Acoustic Guitar with Case

- Prepare & Inflate: Unfold/tape the box; inflate one top hat + one bottom end cap; push in the end-cap corners.

- Bottom-up fill: Seat the case into the bottom end cap and push to the bottom.

- Lock & Top: Drop the center beam (through its opening) to rest on the case shoulders; insert the top hat; tape shut (top-hat compression is expected).

Bare Guitar (No Case)

- Wrap: Slip the fabric guitar bag on, then fit the inflated guitar vest around the body from the back (use the vest’s fold scores as needed).

- Reinforce: Fold and install the center box beam over the neck, then the accordion neck-stabilizer so it rests on that beam.

- Finish: Place guitar into the box; close and tape.

Inflation Tips (Fast, Repeatable Results)

Aeris inflatables are designed for ~12 PSI. If using a shop compressor (often 125–150 PSI), use the Aeris Inflation Kit to dial it down precisely; bicycle/balloon pumps work for low volume—inflate until rigid, not rock-hard. If a chamber stalls, knead the fill valves.

FAQs

Should I detune before shipping?

There’s no universal rule, but a slight detune is a safe compromise—reduces stress without inviting parts to shift.

Is it okay to write “Guitar” on the box?

Best practice is don’t—use orientation/fragile labels only to reduce theft risk.

Final Checklist

- Photos taken; loose parts removed/secured (trem arm, caps, strap, batteries)

- Strings slightly loosened; fretboard and hardware protected

- Headstock/neck immobilized; heel gap filled without creating stress

- Case centered in box; cushioned base; all voids filled; shake test passed

- Seams taped; label protected; box not marked “Guitar”

- Insured for full value; ship early week; recipient knows to inspect on arrival

Why StewMac Makes Shipping Simple

Whether you’re sending one guitar or a dozen, StewMac’s guitar shipping boxes replace guesswork with engineered supports that immobilize your instrument and purposeful compression that keeps everything snug once the box is taped. They save time, space, and—most importantly—guitars. If you want repeatable, pro-level protection without hunting down packing supplies, StewMac’s kits are the easiest path to a worry-free ship-out.

Video Transcription

A Better Way To Ship a Guitar

Paul Lampley: Shipping a guitar used to be a hassle. You have to find a good solid box and it has to be the right size. If it's too big, you'll pay extra for shipping. Then there's packing material, newspaper compresses and gets smaller, bubble wrap leaks air, and you end up with too much space in the box.

That's what breaks guitars: poor padding, and room to knock around during shipping. The Aeris Guitar Shipping System changes all of that. It's a super secure way to hold the guitar during shipment. The Aeris System stores flat and takes up very little space. Look how small these are. This is a three pack, three complete shipping boxes with three sets of inflatables, all in a box that's small enough to store anywhere.

Now you no longer have to buy or find a place to store bulky shipping supplies. It's an amazing system.

Aeris is the industry leader supplying guitar manufacturers and large businesses. Stewmac has partnered with Aeris so our customers can buy the Guitar Shipping System too. There's a version for an acoustic guitar in its case, for an electric guitar in its case, and here's something really special - a secure system for shipping a naked guitar without any case. There's a version for electric guitars and another for acoustics.

Exclusively from Stewmac, you can get three packs and six packs, the complete guitar shipping systems, and a handy pump too. We also offer a foot pedal valve for inflating from your shop's air compressor. That's handy if you ship a lot. Let's pull one from this three pack and see how it works.

How it Works

Each individual cell inflates from this one point, and when they're full, they seal themselves shut. If you were to cut one cell open, the others wouldn't lose any air. They're super firm and resilient, not like bubble wrap. You can pop the corners like this to help cradle the curves of the guitar case. Fit the bottom cushion onto the end of the guitar case, put the guitar in the box, slide the cardboard support beam down over the guitar. This keeps it from moving and also supports the box in the center. Now add the top cushion.

See how these two points stick up? That's part of the design, to press against the end of the box so the guitar can't shift around inside at all. Just seal it up and you're ready to ship. It's secure and lightweight and it's really solid. You've only added air. No extra weight to pay for in shipping. Plus the length and width of the box are precisely figured to keep your shipping costs down. Your guitar is ready to survive trucks, airports, or whatever else comes its way.