Electric Guitar and Bass Assembly Guide, Part 3: Hardware and Neck Installation

Hardware Installation

Drilling holes

It is highly recommended to assemble the instrument prior to applying a finish to a body or neck. This means you must also drill all of the holes (bridge, strap button, pickguard, tuner, etc.) before a finish is applied. This will eliminate any accidental chipping of the finish with the drill bits. If you are working with a pre-finished body and/or neck, start the hole with the drill going backwards. This causes the bit to "burnish" its way through the finish, reducing the chance of chipping out the finish. This also works for cleaning excess paint out of a drilled hole after a body or neck has been finished. Start the holes slowly and if you're in doubt, try a few test holes on an area of the guitar that will be covered by the pickguard, or some other hidden location.

Always centerpunch the hole locations before you drill; this will ensure that the holes are properly located (very important with bridge screws). A drill press is also recommended when drilling bridge mounting holes, especially tremolo bridges. If you don't have direct access to a drill press, have a friend with a drill press drill a series of holes through a block of wood that correspond to the holes required for your bridge. Then put the block on top of the body and use it to guide your drill bit(s). Make sure the block is large enough to give you adequate support, but not too thick so that the drill bit(s) won't go deep enough into the guitar. See below for an example of this drill guide.

Use masking tape to mark the required depth on the drill bit. This will ensure that the holes are deep enough, but not too deep (critical when drilling tuner screw and string tree holes). Lastly, when drilling holes completely through wood, always have a backer board (scrap hardwood or plywood for example) to prevent the wood from chipping out when the bit punches through the back side of the wood.

Be sure to have a good selection of drill bits (a 1/16" through 1/2" drill index is recommended) so that you can properly size the holes for the particular screws. Standard wood/steel drill bits work fine for drilling all of your holes. Brad point drill bits are great in certain situations, but they're not absolutely necessary. Spade or butterfly bits should be avoided—they tend to make oval instead of round holes.

The hole shouldn't be too big (the screw may strip out the wood), nor too small (the hole will be tight and you may twist off the head of the screw or split the wood). The threaded portion of a screw has two dimensions. The outside diameter or peaks of the threads are referred to as the maximum diameter, and the minimum diameter refers to the central core or valleys of the threads. The hole for a wood screw should be the same as, or just slightly larger than the minimum diameter of the screw.

To size a bit, hold the screw against the drill bit (drill bit closest to you), and find the one that is the same size as the minimum diameter of the screw. If the screw has a smooth shank or shoulder, you will need to drill a two-step hole. One will correspond to the threaded portion and the other will be the same diameter as the shoulder of the screw.

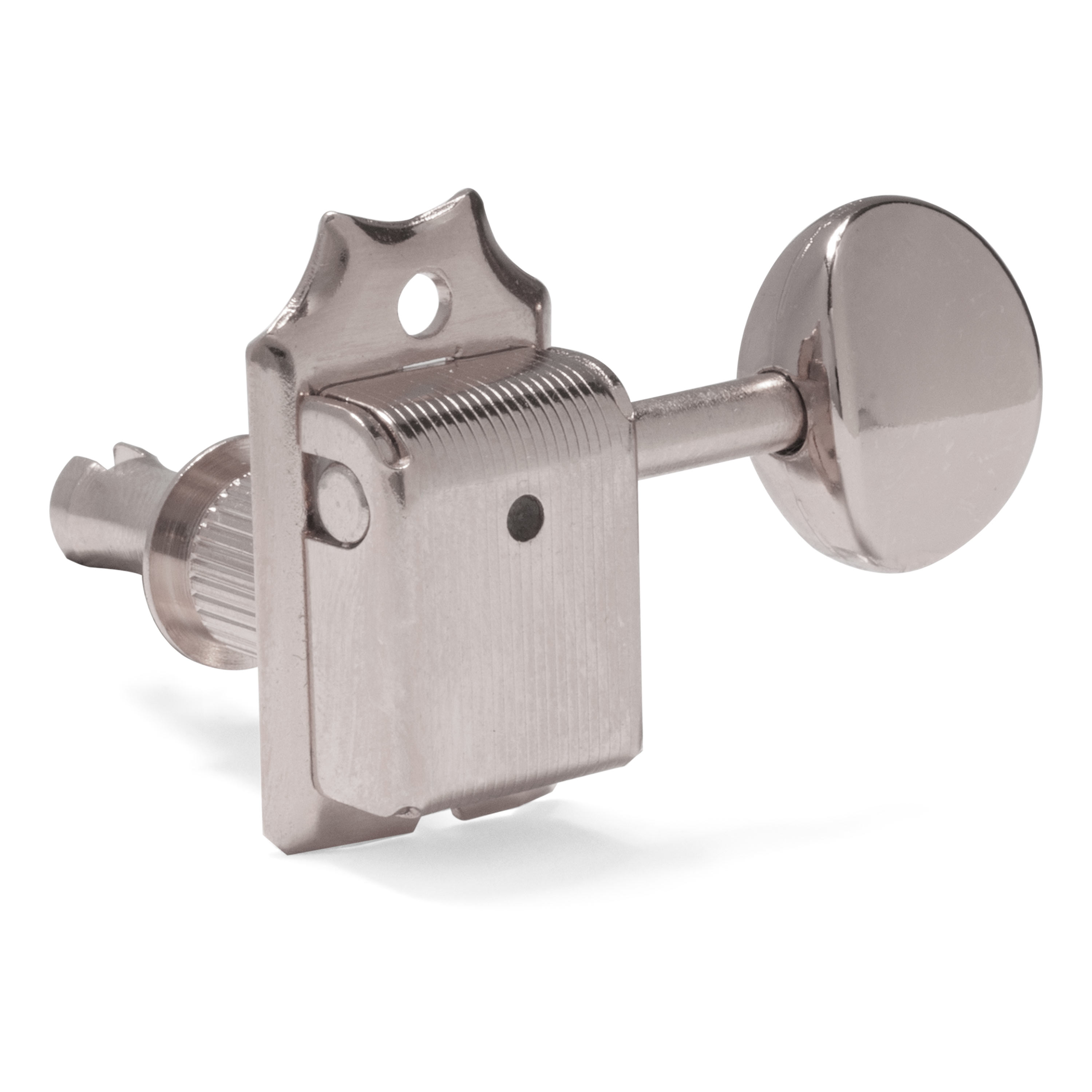

Tuner installation

There are many different types of tuners being used on guitars today. Most of them install easily, and without too much layout. Read any instructions that may come with your tuners to aid you in installing them. Be aware of the size of the hole required for the tuner through the peghead.

Most enclosed-gear tuners require a 3/8"-diameter hole, while traditional Kluson-style tuners use a 11/32"-diameter peghole. Our 22-fret necks are drilled for 3/8"-diameter holes, which will accept almost any tuner on the market. If you wish to use a traditional Kluson-style tuner with a 22-fret neck, you will need to use the #3458 or #3458-G conversion bushings to properly fit the 3/8" peghole.

Press-in bushings can be installed carefully using a small "dead-blow" hammer or a medium-sized Phillips screwdriver (slide the bushing over the shaft of the screwdriver and then tap the handle of the screwdriver with a hammer). Be sure to support the peghead when installing the bushings. It is best to work near or over a leg of your workbench so that you get a solid hit.

Once the tuners can be fitted into the holes you must align them and centerpunch for the tuner screws. Carefully layout the tuners. Be sure they are aligned with one another and that they are square with the edge of the peghead. If the tuners have a threaded hex bushing, snug them finger-tight so that the tuners can be adjusted easily, but won't move when you centerpunch. With Kluson-style tuners it's always good to make a small pencil mark, and then remove the tuners and connect the seven marks with a straightedge. Re-install the tuners and centerpunch on the line. This will help ensure that the tuners line up correctly, since they share tuner screws.

Next, centerpunch the positions of the tuner screws and determine the size(s) of the drill bit for the tuner screws. If a portion of the screw has a smooth shank, you must drill a two-step hole. Hold the screw against the end of the drill bit to determine the depth required, and wrap some masking tape around the bit as a depth guide. Drill carefully and slowly. Don't try to drill the full depth in one plunge; pull the bit out periodically to clear the shavings packed onto the bit.

Place the tuners back on the neck and snug the threaded hex bushings if applicable. Install the tuner screws (a good sharp and properly-sized screwdriver will make this job much easier!) and double-check the alignment. After everything is square and true, check the tightness of the screws and tighten the peghead bushings with a 10mm wrench or socket if applicable.

Locating the bridge

Our guitar bodies are routed for a standard Fender-style 25-1/2" scale neck with 21 frets, or a 22-fret neck with a 22nd fret overhang. To locate your bridge correctly, adjust the high E-string saddle to the last 1/16" of its travel toward the neck (see below).

Now measure 25-1/2" from the nut (at the side facing the bridge) to the point were the string stops vibrating on the high E string saddle (break point). When the instrument is properly intonated, the length of the high E-string is roughly the same as the scale length. All the other strings are longer than the actual scale length. See chart below for some locations based on specific bridges.

To properly locate the bridge, you must use the neck and the pickguard (if you are installing one). Place the neck into the neck pocket and check its fit. It should drop in or be a little snug—you shouldn't have to force the neck into the pocket. If the body is unfinished and you are pre-assembling the instrument (highly recommended!), remember that the finish will make the neck pocket smaller—it will build up on the edge of the rout. Therefore, the neck shouldn't fit too snug if there is no finish on the body, or the neck will be too tight later.

Locate and center the neck in the neck pocket. Use a small clamp with thin wooden shims on the clamping surfaces to hold the neck in place. After you have determined the proper location for the bridge mounting screws, make a light pencil mark on the body, parallel to the frets and the nut. We recommend that you make two small marks, one corresponding to each E-string, and connect the dots with one line. This will help ensure that the line is parallel to the nut.

| Bridge | Distance from nut to center of forward- most mounting screw or pivot post |

|---|---|

| #0025, #0090, #0099 Telecaster-style bridges | 25-3/4" ± 1/16" from nut to center of mounting screws. |

| Floating Tremolo Bridge | 25-1/4" ± 1/16" from nut to center of pivot screws. |

| #0179 Non-tremolo Stratocaster-style bridge | 25-1/4" ± 1/16" from nut to center of front mounting screws. |

| #0577 Schaller Non-Tremolo Roller Bridge | 26-3/16" from nut to center of mounting screws. |

| #1264 Traditional Strat Tremolo Bridge and other vintage-style Strat tremolos | 25-1/4" ± 1/16" from nut to center of pivot screws. |

| Floyd Rose II or #1270 Schaller | 24-15/16" ± 1/16" from nut to center of pivot screws. |

| Floyd Rose or Gotoh | 25" ± 1/16" from nut to center of pivot screws. |

| #0093 Fender® Style Bass Bridge | 35" ± 1/16" from nut to center of rear-most mounting screws. |

Now you must locate the bridge laterally (side-to-side). With the neck in the neck pocket, place the pickguard (if used) onto the instrument. Align the pickguard on the end of the neck and make sure that it properly follows the contours and shape of the body. Tape the pickguard onto the body in its proper location. Now place the bridge on the instrument and align it with the rout in the back of the pickguard and your length mark for the mounting screws. Make intersecting "cross-hair" marks for the mounting screw holes through the bridge plate. If the bridge is a tremolo, make sure that it is moving freely and it's not binding on the edges of the rout. If the pickguard seems to throw the location of the bridge off, you may have to move it slightly so that everything works correctly. Remember the golden rule of woodworking, "Measure twice and cut once!" This is especially important with bridge location and drilling.

To double-check the bridge's lateral location, take a long straightedge and place it along the edge of the neck. Be sure that a portion of the straightedge is over the body at the bridge's location. Compare the two sides of the neck and where the straightedge hangs over the bridge. (Example: the straightedge may be even with the outside of the E-string saddles, the outer saddle height screws, the outer edges of the bridge plate, etc.) Once you are convinced that the bridge is located correctly, centerpunch your marks and drill for the mounting screws/posts.

String grommets

Some bridges require the installation of string grommets the back of the guitar. Grommets should not be installed into an unfinished body because they are too difficult to remove. To properly install grommets on a finished body you will need the following tools:- Hammer

- #1 Phillips screwdriver

- Soldering iron (25-45 watt) with pencil or chisel tip (soldering guns are not recommended!)

- Needle-nose pliers

To install a grommet, hold it with your needle-nose pliers and make sure the chamfered edge aligns with the pre-drilled hole. Next, insert the soldering iron's tip into the opening of the grommet. Be sure to preheat your soldering iron (5-10 minutes) to ensure uniform, quick heating of the grommets.

Now, press down with the soldering iron (loosen your grip with the needle-nose, but don't let go). You're not trying to press the grommet in with the soldering iron, just transferring some heat to soften the finish to allow the grommet to be pressed into the wood. After 3-5 seconds, remove the soldering iron while holding onto the grommet with the needle-nose pliers. This ensures that the soldering iron will pull off of the grommet. Don't let the grommet fall onto the finish; it will melt into it!

Next, insert the tip of the #1 Phillips screwdriver into the grommet and tap the handle with your hammer. The screwdriver will help you guide the grommet into the hole, ensure that it doesn't tip or lean, and keep you from contacting the finish with the hammer while you drive it into place. The grommet should stop just under the top ledge of the drilled hole—don't keep hitting it with your hammer. Install the other grommets using the same method.

Tips on tremolo installation

Tremolo bridges require special attention during installation. You will need special tools to make the job clean and easy. One tool that assists in the installation of a tremolo is a 7/64" extension or "aircraft" drill bit. This bit is 12" long and allows you to drill the two holes for the tremolo claw correctly, without bashing into the body with your drill.

When installing a tremolo system, be sure that the block (the portion of the tremolo that passes through the body and to which the springs attach) is not coming into contact with the sides of the through-body tremolo rout. This will minimize tuning problems with a traditional (non-locking) tremolo. As mentioned earlier, be especially careful when drilling the tremolo post mounting holes. This is the most critical area to ensure smooth, glitch-free tremolo operation.

Most players and builders prefer three tremolo springs for smooth feel and tension. Five springs can give a cool "faux-reverb" effect, especially when the bridge is adjusted to bottom-out on the top of the guitar. The tremolo is harder to push down, but the sympathetic vibration of the springs can be a very nice addition to the tone and sustain of your guitar.

Attaching the neck

Drilling the neck bolt holes is one of the most critical operations in the construction of a bolt-on neck guitar. The holes must be properly sized and located so that the neck is secure in the pocket, and the vibrations and resonance of the instrument are not compromised.

Often a body will have pre-drilled neck holes. In this case simply place the neck into the pocket, properly located and aligned with the bridge, and centerpunch or mark the locations to be drilled onto the neck. You can use the four neck bolts and tap them with a hammer to make the marks in the neck. If the body doesn't have the neck bolt holes drilled, use the neck plate to locate them. The simplest way is to place the neck plate into the pocket and properly position it in the rout (refer to the drawing for the proper location). The measurement "A" is 5/8" for guitar, 1-5/16" for bass.

After locating the plate, centerpunch your marks and drill the holes. Most body/neck mounting holes are 3/16"-diameter, and they are slightly countersunk on the backside of the body. We recommend drilling these holes with a drill press (or use the wooden guide block trick mentioned earlier) to maintain squareness and proper alignment.

Next, you must drill the holes into the neck. After centerpunching the neck bolt locations, determine the proper size drill bit (most neck bolts use a 1/8"-diameter bit) and chuck it into your drill. Place a neck bolt through the neck plate and body. Measure the amount of the neck bolt that extends up into the neck pocket, and mark your drill bit so that it will drill into the neck to that depth. Carefully drill the holes in the neck-when drilling maple or other dense hardwoods, drill the hole in gradual steps so the bit won't get too hot or clogged. Pull the bit out a few times while drilling to clear the shavings packed onto the bit.

String nut

Installing a nut on your guitar neck is one of the most crucial aspects of the instrument's playability and performance. A poorly installed or poorly-shaped nut can cause tuning problems, inferior tone, and poor sustain. For a nut to work well, the slots must be properly sized, located, and shaped. The fit of the nut into the slot is also very critical. It should fit snugly (not too tight) and conform to all aspects of the slot and fingerboard's shape.

The slots must be sized per string and have a round "U-shaped" bottom, to support the full diameter of the string (a "V-groove" slot can bind on a string). Slots for unwound strings should be the same depth as the diameter of the strings, and the depth of a wound string's slot should be half the diameter of the string. For guitars with tremolos, or for players who really bend strings, the slots may need to be deeper.

The slot cannot be too tight or it will pinch or bind the string in the slot. Most everyone has heard the tell-tale "pink-pink-tink" sound of a nut pinching and releasing the string as it is brought to pitch. This will cause tuning problems galore, and is definitely a problem that should be addressed. Depending on the nut material, you may want to lubricate the slots, especially if a tremolo system is being used. Guitar Grease (part #3413) is ideal for lubricating nut slots (and tremolo pivot posts and contact points).

The slot's width should be only a few thousandths wider than the gauge of string that is to be fed through it. The proper width will ensure that the strings don't rattle in the slot-a real tone and sustain killer. The slots should also point to the tuner that the string is intended to wrap around. Lastly, make sure that the slot slopes downward, toward the peghead. The highest (or shallowest) part of the nut slots should be on the fingerboard side of the nut. The peghead side of the nut slot is deeper to ensure proper "string break" over the nut. Just as when you poorly fret a note on a fingerboard (too far from the fret or with not enough downward pressure), an improper nut slot will severely compromise tone, sustain, and overall playability.

We sell gauged nut files that are perfect for slotting nuts. Refer to the catalog and your string gauges to match up a set for your instrument. If you don't want to invest in these tools, a pre-slotted GraphTech nut (#1866) is a good solution. This nut will work well on all of our guitar necks, and the GraphTech material has good tone and won't pinch or bind the strings. Before you can take the slot depths down to their proper height, you must setup the instrument. For now, rough-in the slots, but don't make them too deep.

Strap buttons, string trees, and other hardware

Use common sense when installing the other hardware on your electric guitar. Always check for the correct size drill bit and carefully center punch your hole locations before you drill.

Strap buttons should be located to securely hold the strap in the playing position. The centerline of the attachment screw should be perpendicular to the strap. The design of Fender-type instruments allows strap buttons to be conveniently and easily located. Refer to pictures if you need exact locations for certain vintage instruments.

Before installing a traditional Fender-style string tree, string the guitar. This will help you determine the proper lateral location for the string trees. Refer to pictures of guitars for the location of the trees on various models and vintages.

Until sometime in the early Seventies, Fender used only one string tree on the peghead (for the high E and B-strings). On Strats, this tree is located about the same distance from the nut as the A-string tuner. Telecasters started with the tree near the G-string tuner, but then moved toward the A-string in the mid 50s. If you are using a second string tree (for the G and D) it is generally about 1/8" to 1/4" closer to the nut than the B and E tree. Why use a string tree? It provides enough downward force on the string through the nut—all in the name of tone and sustain.

The string retainer bar for Floyd Rose and other locking nuts is also important. It must be located close enough to the nut and peghead to make the strings follow the curvature of the bottom of the locking nut. If this is not done, and the string locks on the nut are tightened, the strings will go sharp. Look at the nut from the side and you will see the curvature that the string must follow. Lower the retainer bar until the string conforms to the bottom of the nut.

More In This Series

| Part 1: | Introduction |

| Part 2: | Recommended Tools and Supplies |

| Part 3: | Hardware and Neck Installation |

| Part 4: | Wiring and Shielding |

| Part 5: | Setup |