How to stop breaking router bits

Issue 225 September 11, 2014

A customer asked me how to avoid breaking tiny router bits. I answer this question from time to time on the phone, and it makes a good Trade Secrets topic. I talked to Dan Erlewine and Dan made us this video. Check it out!

—Matt Brooker, StewMac Tech Support

Matt Brooker is a luthier, musician and member of StewMac’s Tech Team. Matt’s been with StewMac for three years, and he’s one of the experts who answers your questions on the phone and by email.

- "If you're breaking this little guy, you're using it wrong"

- Dan Erlewine's rules for not breaking router bits

- Tip: Use any plug strip as a footswitch

- Tip: Dan's two-pedal "sewing machine" routing technique

Video Transcription

[on-screen text reads: Stewart-MacDonald - Trade Secrets! How to stop breaking router bits. Dan Erlewine, Stewart-MacDonald]

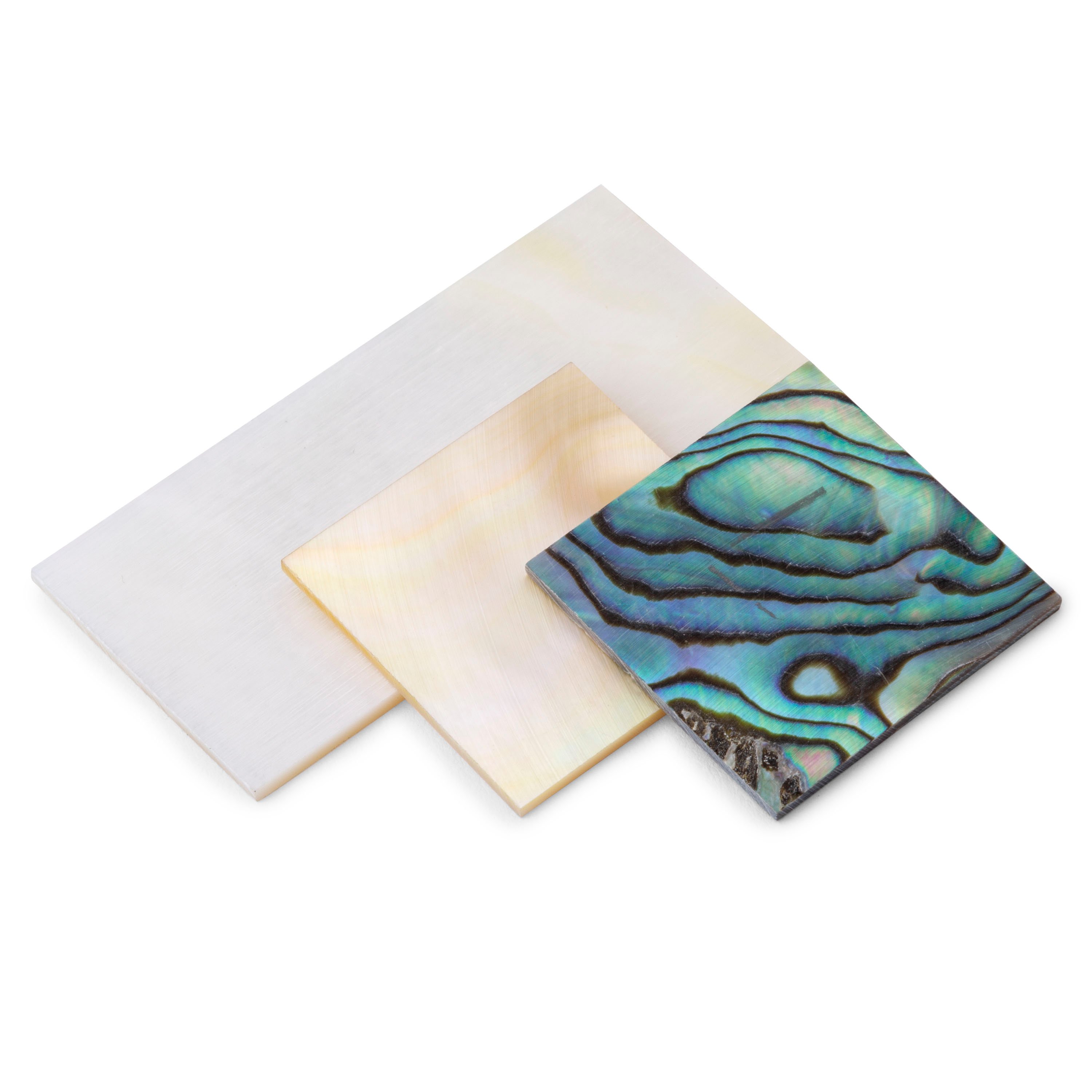

Dan Erlewine: Here's a one 1/32 inch carbide spiral down cut router bit. And next to it is one just like it, but the tip's broken off because it's really delicate. If you're breaking this little guy, you're using it wrong. This is really the last bit that you use when you're doing inlay work. It's for sharp corners and pinpoint accuracy and cleaning up the edges, not for general work. And with any router bit, but especially this, you shouldn't cut deeper than the size of the bit. So I wouldn't cut in one pass deeper than a 32nd of an inch. You also don't want to push the Dremel tool too quickly into the work. It can't take that. That'll snap it off.

Don't cut deeper than the size of the bit

So the rules are don't cut deeper than the size of the bit in one pass. That means if your bits are 32nds wide, don't cut deeper than a 32nd, and don't use the highest speed on the tool just because you have it [on-screen text reads: Stablize your Dremel - Precision Router Base from StewMac]. Try the different speeds and see what feels best for that piece of wood [on-screen text reads: Experiment with speed using scrap wood]. Here I've got the Dremel tool on five. I'm working on a scrap piece of Rosewood here, and I've got my Dremel base turned away from me so that you can see the work.

Don't rush! let the tool do the work

Don't push too hard with your tool. Don't force it to go too fast into the wood. Remember, wood has hard and soft grains, and you might be cruising along with a soft grain and run into a hard one, and that will cause the bit to snap for sure [on-screen text reads: Racing into a grain line will snap a bit]. So don't go zipping through it without feeling the wood.

Save the fine bits for details

For all but the smallest patterns, use as big a bit as you can to clear out the center of your pattern and only use the little bits for fine corners and detail work.

Two pedal "Sewing machine" routing technique

It's tough to have two hands on a Dremel base [on-screen text reads: Precision Router Base] and reach around and try to turn the machine off, especially if you're wearing an opti-VISOR like I do [on-screen text reads: See details as clearly as Dan - OptiVISOR Headand Magnifier from StewMac]. So use a plug strip to turn the thing on and off. The little dust blower hose [on-screen text reads: Mini Air Pump] is plugged into the same strip. I've perfected the technique of holding a vacuum and the base and not slipping. Now I've got the pump blowing the dust away and the vacuum picking it up while I route, and I only have two hands.