How to fix this guitar if my elbow's stuck in the soundhole?

Issue 142 June 23, 2011

|

if my elbow’s stuck in the soundhole?! |

|

||||||

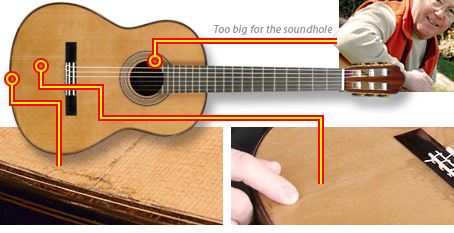

Hey, it actually happened to me! Years ago I got my elbow through a soundhole, then couldn’t get it back out. No kidding. I had to soap my arm to get it out of there. Hey, it actually happened to me! Years ago I got my elbow through a soundhole, then couldn’t get it back out. No kidding. I had to soap my arm to get it out of there.Try doing that one-handed, while your other hand has somebody's guitar stuck on it! I felt pretty silly as you might imagine, and this isn't something I’ve talked about very often. ;-) This classical guitar came to the shop because its top was buzzing. Looking inside with a light and mirrors, I found the problem. At the tail of the guitar, there was a gap between the top and the tailblock. |

|||||

|

Pressing on the top outside, I could see a gap open and close inside. It’s almost too small to see in this photo, but it’s there: the lining between the top and the side had come unglued. |  Flexible Lighted Inspection Mirror Flexible Lighted Inspection Mirror |

|||

|

|||||

| This guitar must have suffered quite a blow. On the outside, there was a “crunch” fracture along the binding, and a long crack heading toward the bridge. A bit of staining showed where someone had tried to fix the crunch, and a light area along the crack was probably from their sanding. Even with my fancy repair gizmos, I couldn’t maneuver well enough to get glue where it was needed, much less complete the work before the glue started to dry. Even if I could, my glue job would be sloppy as heck and hard to clean up. I decided to “think outside the box” by removing a section of binding to access the loose joint and get at the problem. |

|||||

|

The wood binding had multiple layers divided by thin strips of maple. I used a ball-bearing binding router bit to remove the outermost layer of rosewood binding. I left the intricate inner laminations untouched. Removing the rosewood was enough to give me access to the joint. |

Binding Router Bit Set Binding Router Bit Set |

|||

|

Now I could slide feeler gauges into the loose joint along its entire length. |

Offset Disassembly Knife Offset Disassembly Knife |

|||

|

With the glue in there, I clamped the joint shut with spool clamps: cork-padded dowels sliding on all-thread rods. The plastic straws protect the guitar's finish from the threads. |

Spool Clamps Spool Clamps |

|||

|

I cut a strip of rosewood to size, soaked it in water for 30 minutes and bent it to shape on a bending iron. |

Bending Iron Bending Iron |

|||

|

Day 2: covering my tracks The next morning I shaped the ends of the rosewood strip to match the curves left by the router bit on each end of the routed ledge. |

Franklin Titebond Glue Franklin Titebond Glue |

|||

|

|||||

|

I glued the strip in with hot hide glue, using rubber binding bands to clamp it in place. |

Rubber Binding Bands Rubber Binding Bands |

|||

|

When the binding was dry I filed, scraped and sanded the new wood flush with the back and sides. |

Natural Wood Bindings Natural Wood Bindings |

|||

|

Anxious to hear if the buzz was gone, I strung the guitar to pitch before touching up the finish. |

Classical Guitar Bridge Classical Guitar Bridge |

|||

|

No buzz! And I never even had to monkey around in the soundhole! |

||||