Finding the right location for a guitar's saddle slot

When you make an acoustic guitar bridge, cut the saddle slot after installing the bridge on the guitar top. With the bridge in place, you can locate the exact saddle position for good intonation. Here’s how I do this in my shop...

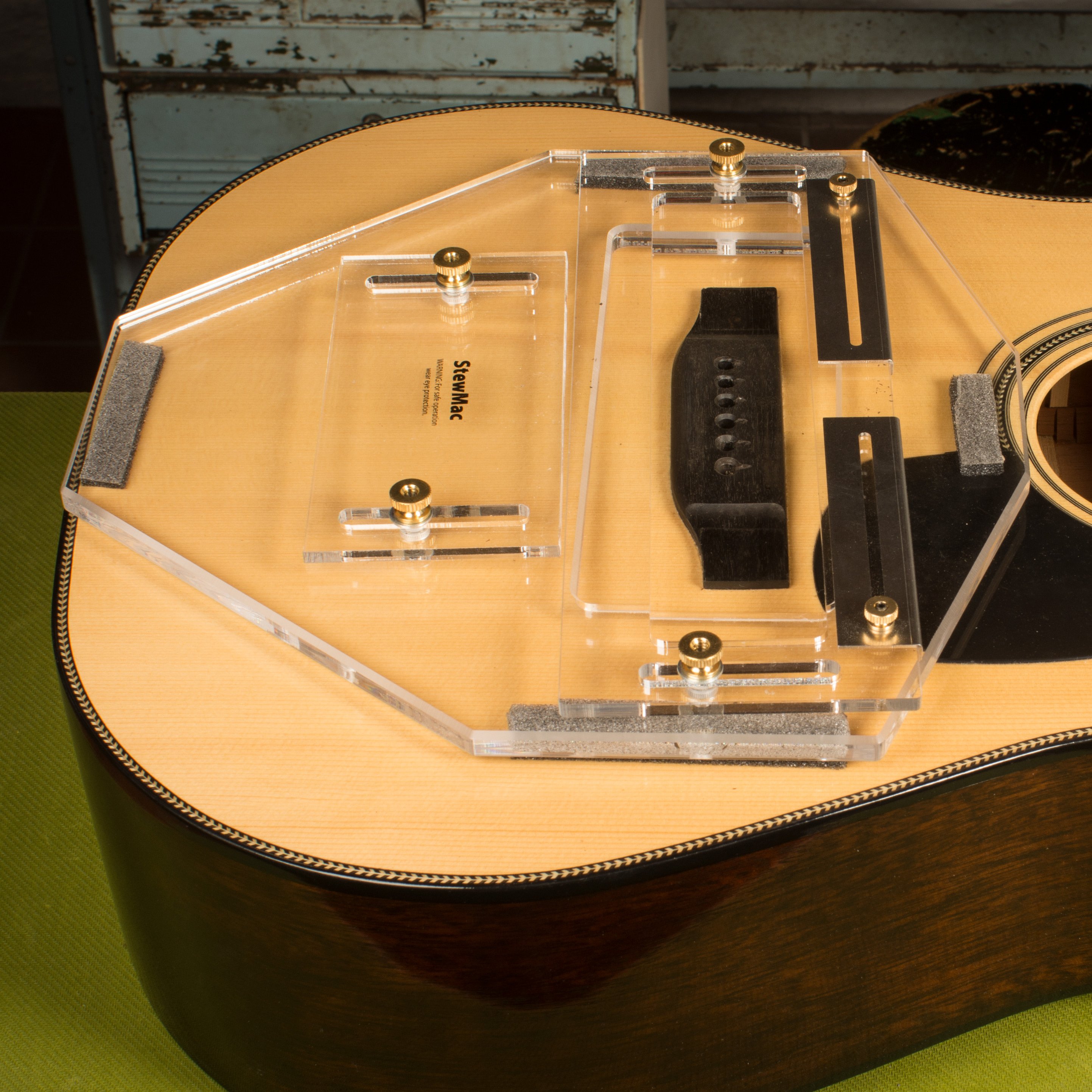

Installing this replacement bridge meant carving the blank to match the original, then finding the saddle location. If the saddle's not in the right spot, at the correct angle, the guitar's not going to play in tune. I invented The Intonator to make this job easier and more precise: it's a brass saddle tool that adjusts each string individually. Now I can tune the guitar to pitch and tweak each saddle position, guided by an accurate strobe tuner. Once these six sweet-spots are located, put a pencil mark along the front and back of each Intonator saddle; the intonation point is midway between these two pencil marks. With a sharp awl or scribe, make a small indent at this point for each string. Now you know where the saddle has to go: it needs to cover these six indents. This determines the angle and the width of the saddle slot. With a razor knife, scribe two parallel lines just wide enough to enclose the six indents, and bingo -- that's where to rout the slot! The wood between the scribed lines will be Dremeled away using a Precision Router Base. The Saddle Routing Jig controls the angle and length of the cut so that the router exactly follows the line you’ve set, and using a downcut router bit means you won’t get fuzzy, sloppy edges. Use a bit that’s smaller than the slot you want, and cut down the middle of the slot. Then carefully widen the slot by making a pass along each side, removing a very little bit of wood. This is the secret to getting a tight-fitting saddle. This Intonator technique works equally well on curved bridges and flat ones. It even mimics the curve of a radiused saddle when you 1, 2, or 3 small brass tubes over the adjustable pieces: each tube raises the string height. A Dremel tool is for delicate work, and I never ask it to plow through the solid hardwood of a bridge. Instead, I first create a series of holes along the length of the slot by plunge-cutting. Then when the Dremel cuts the slot, it's connecting the dots, and there's much less wood to handle. In the Saddle Routing Jig, the router base rides on a sliding platform that can be tipped in its slot to lift the Dremel's router bit up out of the cut. I move along the slot path this way, lifting and lowering the cutter, removing wood with a series of holes. Your router bit must be smaller than your final slot width! For a 1/8" slot, use a 3/32" router bit. The smaller cutter lets you gain the final saddle slot width by degree. You'll get a more accurate cut, and a better fit. But keep in mind that small bits break easily. Don't try to hog out a lot of wood at once. Shallow cuts are best. Make your rout in several passes for the pro results! Once you've plunged the holes from end to end in the saddle slot, rout away the remaining wood to connect the dots. Then, holding the router base firmly, cut back and forth to clean up any remains of the dots (there won't be much there to cut). Now you're ready to create your final width by removing a little wood from the sides of the slot — just "kissing" the slot walls.Find the right spot for your bridge's saddle slot!

To place the saddle, find each string's intonation point

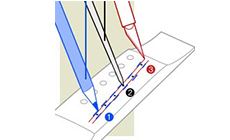

Punch some holes before routing the slot

Use a smaller bit!