Custom-shaping a replacement pickguard for a 1990s Gibson

Custom-shaping a replacement for this beat-up Flying V pickguard

This thing’s seen better days, and off-the-shelf replacements didn’t fit.

I get a call from my pal Gavin Glover, who recently moved to L.A. to pursue fame and fortune with his band the Apocalypse Dudes. The pickguard on Gavin’s 1990s Flying V was falling apart; he bought two replacements, but neither one fit the screw holes in his guitar.

I had Gavin send me the original so I could copy it and make him a new one. A few days later the battered guard showed up in the mail.

The pointed tips were broken off, and the area where the jack plugs into the guard had multiple cracks—this thing wasn’t going to stay together much longer!

The first step in making a replacement was to cut a template to match the shape of this guard. That template will guide my router as I cut the new pickguard.

Making a custom template

I didn’t want to use up a piece of acrylic for a template that I might never use again, and I didn’t have any suitable plywood on hand. But I did have some scraps of .083" pickguard material that were just big enough for the job.

With small pieces of double-stick tape on the back of the original pickguard, I stuck it to one of my scraps.

I scribed the shape of the old guard onto the pickguard scrap.

I attached my scribed piece to a second scrap, using plenty of double-stick tape. I want these two pieces to stay together permanently, making a double-thick piece for cutting my template.

Cutting with a coping saw, I roughed-in the general shape. (A bandsaw would have been a lot quicker!)

Using the original guard as a guide, I drilled the holes for control pots and mounting screws. Copying the original screw holes means my replacement guard will be custom-fitted to Gavin’s guitar.

I removed the original guard and used nut shaping files to very carefully bring the edges of the new template in to my scribed lines.

I used an acrylic humbucker template to rout the pickup holes.

I don’t have a fancy setup for this, just a cheapo router table ($25 at a yard sale). It works great!

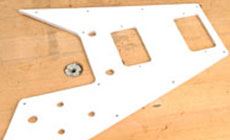

The finished template

My custom template is shaped just the way I want it — a cleaned-up version of Gavin’s original, with all the holes in the right place.

Made of two layers of .083" pickguard material, it's thick enough to follow with a router for cutting the actual pickguard.

From here on, it’s routine pickguard-making: double-stick tape holds my template to the laminated material, a coping saw roughs in the shape, and a drill press adds the holes.

The pickup shapes will be cut on the router table, but first I’m using a forstner bit to hog out most of the material to be removed. This'll make it easier to cut these holes with the router bit.

With the holes drilled and pickup routs semi-cleared, we are ready to hit the router table to clean it up.

The ball-bearing guide follows my template while the bit cuts the pickguard.

First I cut the perimeter, then cleared the pickup routs.

Another pass with a beveling bit creates the slanted edge that shows the white/black/white layers.

Countersinking the screw holes is the last step, and we have a finished guard!

I popped Gavin’s pickguard in the mail, and it was back in L.A. three days later. He’s a happy customer! And I have a template for a 1990s Flying V pickguard on my wall in case another one ever comes through the door!