New ways to use the Guitar Repair Vise

I’m training a helper in my shop. This guy, Big Red, has always been a dependable worker, but now he's learning new things, doing more jobs, and having more fun! I’d like to show you how I've been improvising with my guitar repair vise, but even if you don’t do tricks with yours, StewMac’s already customized it:

Pretty flexible for cast iron!

I’ve been teaching my vise to do tricks

Who says a vise has to sit in the corner?

Standard installation

This is the most everyday-useful setup. You can mount the vise in two ways:

- With the the 3-legged support on top of the bench. This puts the top of the jaws at about 8" above the benchtop.

- Or put the 3-legged support under the bench, lowering the jaws by about two inches. This is my preference. The picture shows the protective felt I use for vise padding.

If your benchtop is less than 1-3/4" thick, make a wooden spacer to add thickness for mounting the vise (drill a hole for the bolt).

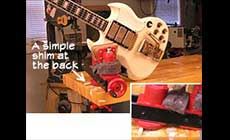

Tilting the vise

For neck setup involving action and intonation, I clamp the guitar in the playing position — tilted the same way it will be when held by the player. I can do this by putting a shim under Big Red. I loosen the wing nut under the bench, insert the shim, and tighten everything back down.

To tilt the vise this way, the mounting hole must be enlarged. The thicker your benchtop, the larger the hole.

Be nice to your dentist!

Let me show you this oddball workbench. My dentist gave me his old dental chair when he updated his equipment. I removed the chair and kept the hydraulic lift. Now it’s a workbench that goes up and down at the push of a button! -Dan

Right angle mounting

For a 90° angle, you can make a simple mounting block:

This block of mahogany under the bench is held by two 1/2" lag bolts through the benchtop. With Big Red mounted this way, I can hold guitars vertically. The vise is tucked back in so only the jaws stick out. This works for a lot of guitar-holding operations

Here’s another angle

A block bolted to the edge of the workbench with a single lag bolt, allowing Big Red to swivel. This was the first “unorthodox” vise mount I ever tried, and it’s been really useful.

Do yourself a favor and give your Big Red a 30-minute lube-job. You’ll be happy you did. With the vise on its side, remove the black steel rail. Scrape any paint off the machined surfaces of the cast iron jaw which travels along the rails, and run a mill file over it. Dress the black rail with 80-120 grit sandpaper, then give the parts some light oil.

Super-adjustable!

Our angle vise on a ShopStand will grip the square casting of Big Red and let you do just about anything. Big Red becomes a gymnast, able to spin 360°, tilt 90°, raise up and down, and hold a project as firmly or gently as you wish. The sky's the limit!