One dead string driving me crazy! (Transducer trouble...)

I almost struck out!

This TeleAcoustic came into my shop because the saddle transducer had a dead string; the low E sounded weak and plonky. My first guess was that the trouble came from a too-high, tipped-over saddle.

Maybe this is the trouble?

This saddle was overly tall and pulled radically forward by string tension, so maybe it couldn’t move freely enough to transfer string vibrations to the transducer. This TeleAcoustic strings up from the back like a solidbody Tele, with strings running through from the back of the body, without bridge pins. That means the low E meets the saddle at a really steep angle, applying more forward pressure than on a typical acoustic bridge.

In adjusting this guitar for better playing action, I found that the saddle needed to be shorter — which was a step in the right direction for reducing that acute angle on the E string. The top of the saddle had a good shape to it, so I lowered it by sanding material from the bottom. When I put the saddle back and strung the guitar to pitch, the dead E string came back to life!

But it didn’t sound right for long.

Pretty soon it became clear that the string was sounding dead again.

A Swing and a miss: Strike One

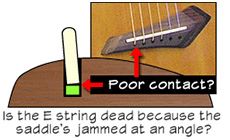

Maybe this is the trouble?

That low E string was still pushing the saddle forward more than normal. I tried something new: rounding the bottom of the saddle. I figured a rounded shape would make decent contact with the transducer even if it’s tipped at an angle.

It worked! The E-string was back in business. I dressed the frets, made a bone nut, left the saddle as is, and shipped the guitar back to Tony, the guitar’s owner. Tony was happy.

But Tony wasn't happy for long.

A few days later Tony was back: the string sounded dead again. What the heck?

I called Fishman Transducers to get their reaction to this round-bottom saddle idea. Frank Padellaro in Customer Service said it makes sense, although it's likely to have less bass response than a properly-fit saddle with a flat bottom. I think it's a good “Plan B" for a tipped saddle. My preferred “Plan A” would be replacing this factory pickup with a new Fishman Acoustic Matrix.

A Swing and a miss: Strike Two

Maybe this is the trouble?

Now I started thinking that the saddle slot wasn’t really flat, resulting in poor contact at the low E string. I removed the transducer so that I could rout the saddle slot flat.

This created a puzzle:

If I remove this pickup and pull the cable out, how will I snake that cable back through the guitar to reinstall the pickup after routing?

The solution was super glue and heavy braided fishing line. I desoldered the cable at the output jack, and superglued my fish line to it. I used heat-shrink tubing to protect the glue joint, and pulled the cable up and out; now the fishing line runs where the cable used to be. With #20 super glue, I fastened the line to the side of the hole in the bottom of the slot, where it stayed while I routed. After routing, I was able to hook the line and pull it up. After regluing it to the cable, I was all set to pull the cable back into place.

Routing the saddle slot finally proved my theory that the slot wasn’t flat: as the router did its cutting, it revealed that the bottom of the slot rose and fell unevenly. Finally I had an answer to the pickup problem!

He swings and connects!

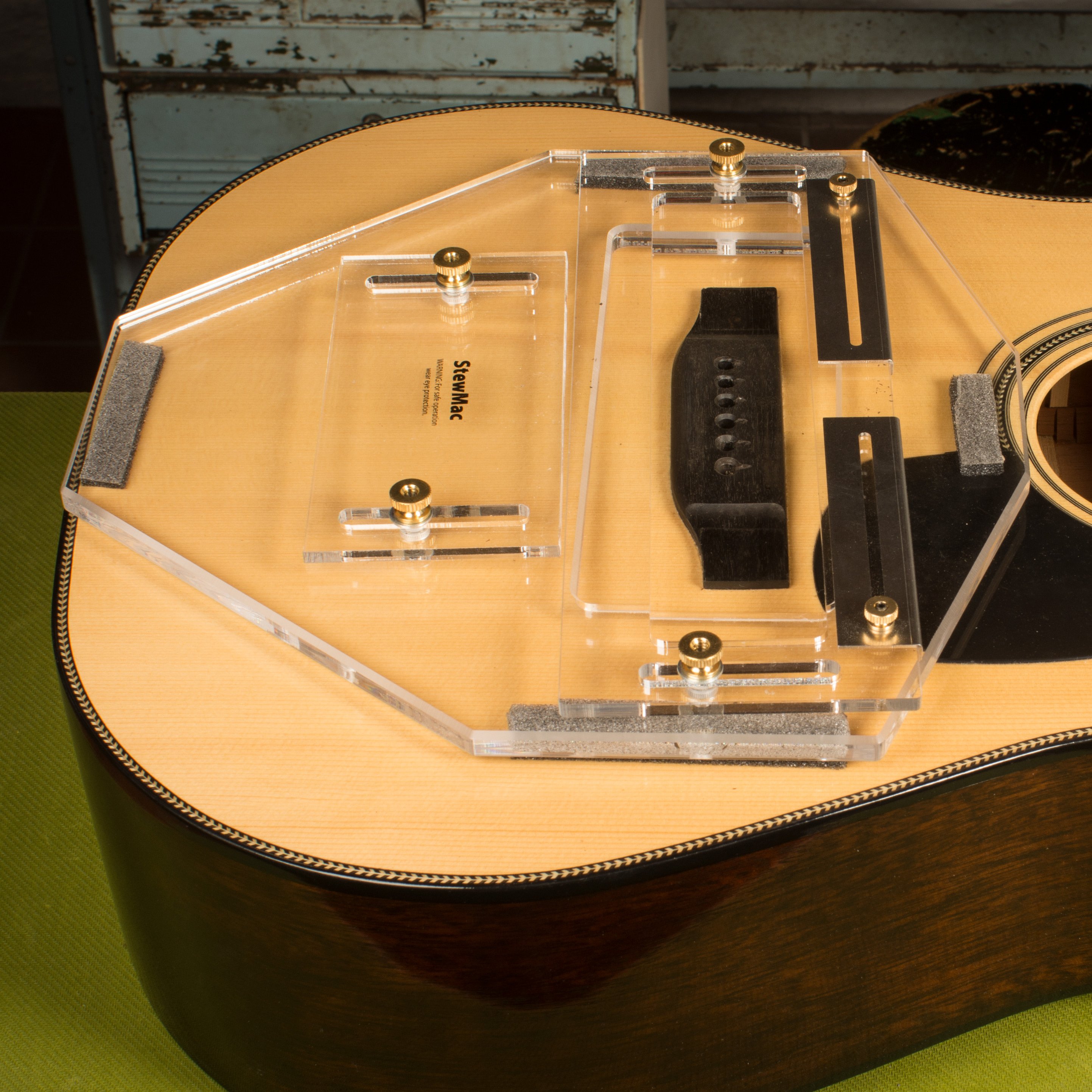

Here are the tools I used to rout this slot:

A Dremel tool with a down-cut router bit did the job in our precision router base and saddle routing jig. I flattened the slot little-by-little, lowering the cutter bit just enough to expose bare wood, until it was flat-bottomed from end to end. I reinstalled the transducer.

I used an output jack wrench to tighten the strap button jack, reaching into the access cavity in the back of the guitar. (The guitar is covered with gray protective felt to protect it while I work. Little chips and dings become part of a guitar’s character, but I don’t want to add any character on my workbench!)

As I turned the wrench, the jack wanted to rotate with it rather than sit still and be tightened. So, I held the strap button with Vise-Grips (padded with a piece of leather).

Well, that's about the toughest bridge saddle installation I've ever run into!