Carlos Santana's Strat: repair and setup

Santana Strat Saddle Setup. Working on Carlos Santana’s vintage Strat

It was a treat to have Carlos Santana send me two refret jobs last December. They turned out well, he’s happy, and we’ve got some good tips for this Trade Secrets!

One of the two Santana guitars was a ’63 Lake Placid Blue Strat with a neck that was twisted so badly that nobody thought it was salvageable. That neck had been given up for dead, but it came back to life on the Neck Jig!

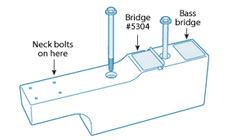

If you use the Neck Jig for your fretwork, have you made yourself a surrogate body for it? This is described in the instructions that come with the Jig. For bolt-on necks, it’s a stand-in for the guitar body: bolt the neck on, string up with a top loading bridge, and you’ve got easy access for adjustments. (And the vintage guitar body stays safely in its case while the work is going on.)

I use mine for bolt-on neck refrets, and I've modified it by adding the two body-shaped wings you see here. For setup work, this makes mine more lap-friendly than the simple block of wood.

For adjustments, I like our new truss rod wrench for Fenders. It really fits a vintage Fender adjusting nut without slipping or damaging the slot.

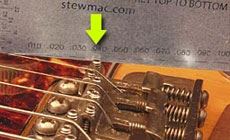

The other Strat was a sunburst from Fender’s mid-60s transitional period. All the bridge saddle height-adjustment screws protruded way above the tops of the saddles — measured with my string action gauge in this photo. Too-tall saddle screws are very uncomfortable: they dig into your hand. As the last step in a setup job, I shorten them and smooth their tops.

Rather than alter the vintage saddle screws, I labeled them and stored them in the guitar case. I used new screws for the setup. Fender makes these screws in four different lengths: 1/4", 5/16", 3/8", and 1/2". One of these sizes always gets me close to my goal, then I grind them to the perfect length.

A few screws were rusted in place and I needed to remove those saddles to work on them. I recorded the exact location of each saddle with a caliper before removing it just to be safe. (If Carlos is happy with the intonation, far be it from me to change it.)

To custom grind each screw to perfect length, I used a surrogate saddle to hold the screw — making a nick to mark the amount to be removed with my diamond nut file. (That’s an Allen wrench mounted in a wooden handle.)

Then I trim the bottom of the screw to length using a stone wheel on a Dremel Tool in the precision router base. I turn the screw with the Allen wrench to create a chamfer on the end.

Finally I carefully de-burr any sharp edges by holding the saddle in my nut/saddle vise and just kissing it with the smoothest cut of my nut/saddle file.

I had a lot of fun on this job, and got it back to Carlos just right before Christmas.

Later, I got to meet Carlos backstage at the NAMM musical merchandising show in Anaheim:

Carlos also needed a new bone nut; the original had served it's purpose long ago and was resting on a pretty thick wood shim (shown to the right of the used nut). That can't be good for tone.

When all was done, Carlos' Strat had .065" action at the twelfth fret (a little over 1/16").