Lubricating guitar tuners

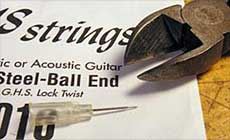

Do your old guitar tuners need a 50,000-song oil change? Get them working smoothly again: flush out the dirt and dried-up lubricant, and oil the gears. Here’s how we grease monkeys do this in my service station: One side at a time, I clamp the tuners into my nut & saddle vise and flush them out with naphtha solvent — forcing the solvent in and out with a plastic pipette. This dissolves the old grease. Don’t contaminate your naphtha by dipping the dirty pipette back into the can. Instead, pour some naphtha into a mixing cup. The naphtha drains out and dries quickly, and I don’t worry much about any solvent remaining in the housing — it will mix with the petroleum jelly that I’ve loaded into my “grease gun” (a large-size glue syringe). Why push the grease through a full-length needle? Instead, I trim the needle short with nippers. The trick is to slide a .016” guitar string into the needle before cutting. This keeps the tube from collapsing as it’s cut. The glue syringe makes a great grease gun. I leave this one loaded with petroleum jelly, a grease that contains no silicone. (Keep silicone away from instrument finishes because it resists finish touchups and is next to impossible to remove.) In a pinch, you can make a tiny grease gun by cutting the top off the squeeze-bulb of a pipette. Fill it with grease, and use any 1/2" round rod as a plunger. Use a power screwdriver and an EZ-Winder to wind the tuner forward and backward rapidly as you squeeze in the petroleum jelly. The moving parts spread the grease to where it’s needed. These tuners are working smoothly now, and ready for lots of miles before their next scheduled maintenance!Tune-up Special at Dan’s Garage:

Lube job for tuners

Let's give these old tuners an oil change

Here’s a neat trick!

A make-it-yourself syringe: