Safe Slot Guitar Nut Guard

V-1823

Stop your string slot file before it cuts too deep and the nut is ruined! StewMac's Dan Erlewine and Don MacRostie, the inventor of the tool, show how it works.

Video Transcription

[on-screen text reads: Safe Slot Nut Slotting Guard]

Dan Erlewine: I'm doing the final setup on this Gretch Roundup from 1955. I've worked on it for months. One of the things that I did was re-thread it completely. And now I'm about to glue the nut in. The cool thing is it's the original nut and that's rare when you do a re-furb, they don't normally fit. This one was a little bit on the tall side, so I'm dropping those strings into the perfect range. I'm using the Safe Slot Tool to do this with, because it keeps me from going too low and blowing that nut. I'll show you how this tool works, here's Don MacRostie, the inventor.

The problem with just using feeler gauges when slotting nuts

Don MacRostie: I've been using feeler gauges for 25 years or more to make filing slots in nuts safe. That is, so I don't go too deep. The file hits the Feeler Gauge and stops at the right depth. The problem has been holding the feeler gauges. They'll rock on the fretboard and they'll twist against the nut. And either of those will cause an error in the slot depth.

How to use the Safe Slot Nut Guard

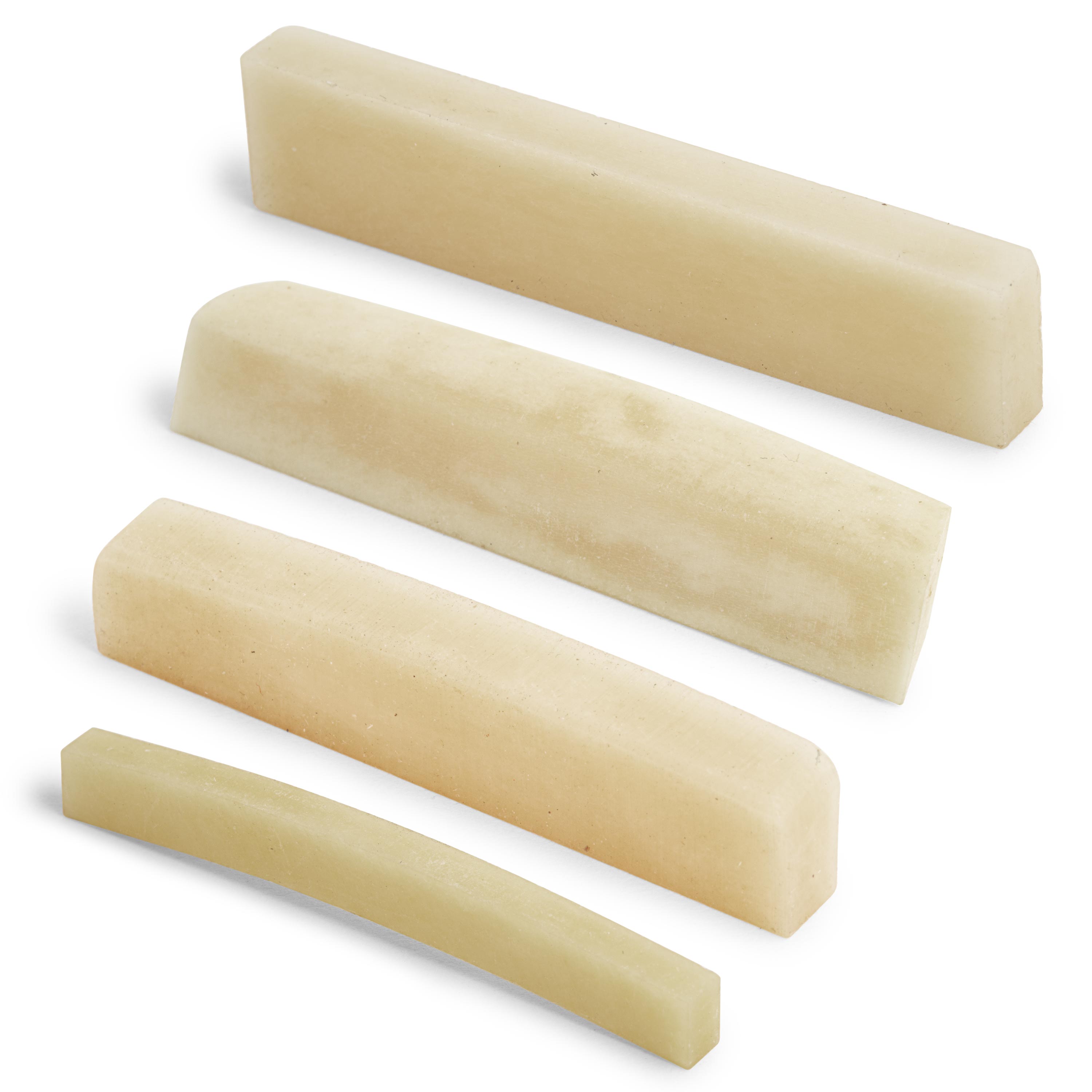

Always looking for a better way, I came up with this tool. This holds the feeler gauges just like I want them. Now, I'll show you how to use it. So I have to measure the gap between the fret tops and the fret board. I do that with feeler gauges and I find the ones that will go. I line right up on the string line and that feeler, that pair will go if I change it to these 1000th bigger, it won't go.

So, I write down the number that goes, which in this case is .035. I do that for each string, so I have four numbers written down from mandolin, E, A, D, and G. Once I have those numbers written down, I've found that I need to raise it up by a factor. I use .006 for the E, add a thousandths for each string. When I get to the base G string, I'm raising at .009. 6, 7, 8, 9.

And for the A string, I come up with .042. That's 35 plus seven. That tells me how much feeler gauge to put in. I do it by adding a 22 and a 20, that's 42. Now I tighten down the holder, the tool, so that it brings a feeler gauge, so it touches on the outer edge, but not so much that it humps up in the center.

The tool has a slanted call on it. Make that slant line up with the fall away of the peghead. It's designed to take care of the round that happens right at the nut. Once I have it pulled down correctly, I select the file for that string, which is a 16 and I'm ready to file.

I want the exit ramp to be about seven degrees and I want the string ramp toward the tuners to be at least online with a peghead. So I'm filing in a curved motion like this, to create the bottom of the slot in a slight round.

I'll file until the file just touches the feeler gauge. With the string slots at the proper depth, now the nut is too tall. I'm going to take off the top of the nut. I'm going to shape the ends and the face and polish it and I'll be done.

Dan Erlewine: Good job. Hey, you got time to hang out afterwards and do a little picking?

Don MacRostie: Yeah, let's pick a tune.

Dan Erlewine: Cool.

[Dan and Don are playing guitar and singing together]

Dan Erlewine and Don MacRostie: Dry all the rain drops and hold back the sun. My world has ended, my baby's gone.