Thread Detective for Guitars will find the correct fit for guitar parts

V-1809

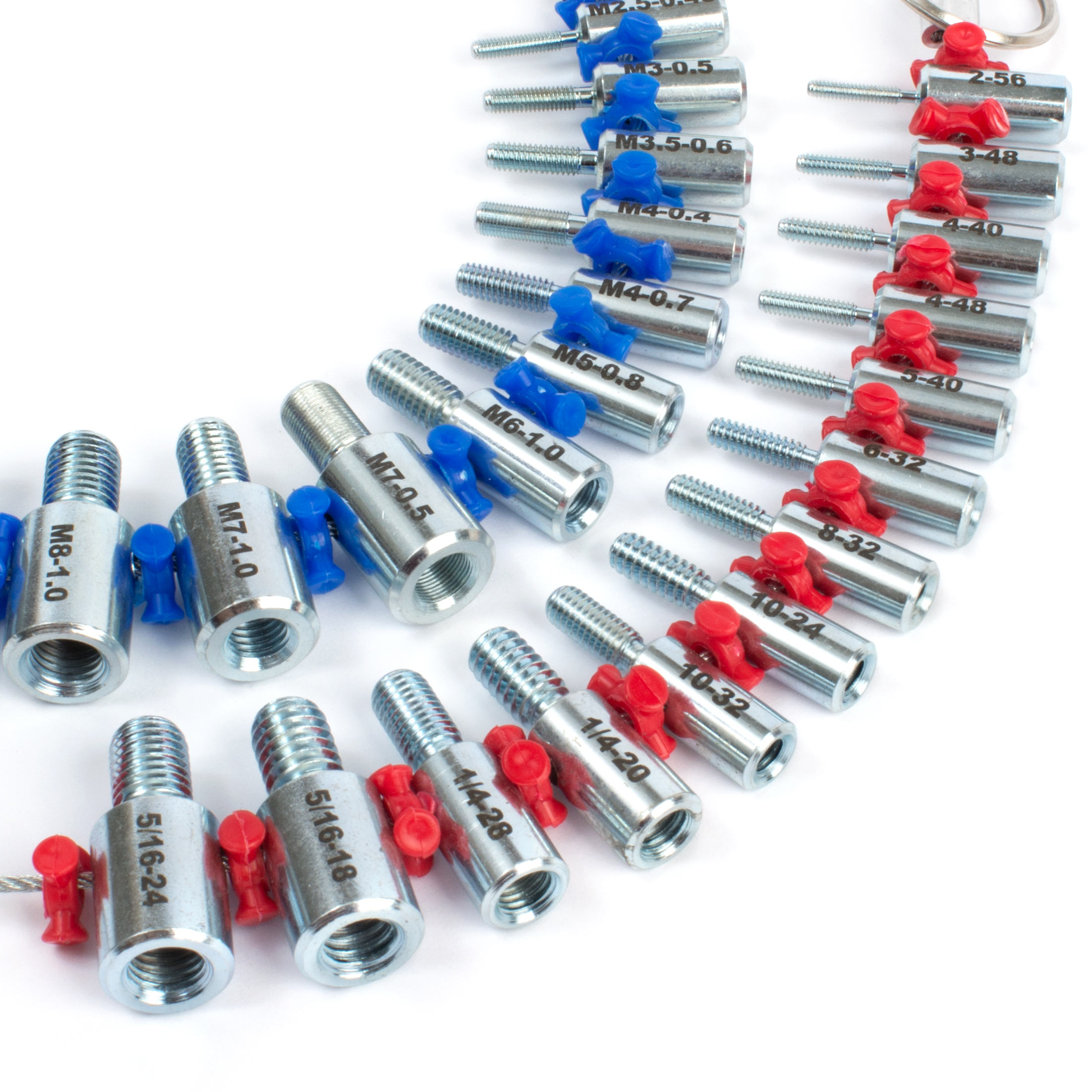

No mismatched threads or ruined parts! Quickly identify metric and SAE thread on screws, nuts, tailpiece studs, and just about any part on your guitar. This special set was created exclusively for StewMac customers.

Video Transcription

[on-screen text reads: Stewart-MacDonald - The Thread Detective for Guitars]

No mismatched parts. No ruined threads

Speaker 1: Screws, bolts, nuts, saddles, I get a lot of small guitar parts in my shop. Just because two parts look the same doesn't mean they're interchangeable. Manufacturers use a lot of different threads for their parts, and toggle switch knobs are a good example. This one doesn't want to thread on because it's too tight of a fit. With this one, it just drops right down. It's too big. That tells me this one's probably an 8-32, like what you'd find on a Gibson switch.

Check metric and standard threads

With the Thread Detective, you can check all the different metric and standard threads you'll find on most guitar parts. Epiphone switches usually use a pretty unique metric thread, an M3.5 by 0.6, and checking that with the Thread Detective, it tells me that this knob is going to be a good fit. A lot of times you'll find SAE threaded parts on guitars built in the US and metric threads on guitars built elsewhere, but that's not always going to be the case.

Take this Gibson for example. A lot of the parts on a Gibson are fairly standard. They almost always use an 8-32 thread for the toggle switch nut, 5/16-24 threads for the stop tailpiece studs, 3-48 thread for the humbucker height adjustment. The truss rod nut almost always has a 10-32 thread. The original Gibson Tune-o-matic bridge, the ABR-1, used height adjustment posts and thumb wheels that had a 6-32 thread, also SAE.

But in 1977, Gibson introduced the Nashville Tune-o-matic bridge. They contracted Schaller, a German company, to manufacture the hardware. Since Germany uses the metric system, Schaller used a metric M5 by 0.8 thread for the height adjustment studs. And that's the same metric thread that you'll find on Nashville Tune-o-matic bridges to this day. So here we have a guitar that was built in the US and has parts that are SAE thread and parts that are metric.

It's not uncommon for guitar builders in one country to use parts that were made in another country. So you never really know for certain what you've got without checking the thread. Before the Thread Detective, we used to use a gauge like this to measure screw threads. We had to line up the tiny little teeth on the gauge with the threads of the screw to see if they matched. It's pretty tough to see on these finer ones, and this gauge actually doesn't even go fine enough to measure the 3-48 threads on this humbucker height screw. Even if it did, you can imagine how hard it would be to see those teeny tiny threads and whether they match up with the teeth.

This kind of a gauge needs to be coated in oil to keep it from rusting, and tool oil is not the kind of thing you want to get on a guitar finish. These are chrome plated steel, so there's no oil and they won't wear out. You could use them to check external or internal threads all in one tool, and it's just a heck of a lot easier to use. You just screw it in, and you know it fits.