eBay mandolin: fret work and using JB Weld to rebuild a truss rod nut

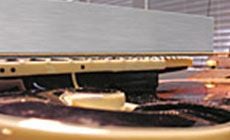

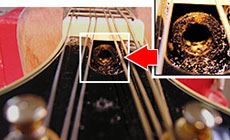

My customer “won” this Fender F-style mandolin on eBay for $200. It retails for $850, so he got a great deal if I can fix it inexpensively. Let’s see what kind of troubles it has... Fret buzz from loose frets An easy fix, using super glue and car wax. Fret buzz from a warped neck Inspecting the mando in the repair vise, this problem led me to the next one: Stripped-out truss rod nut I used JB Weld to fix this one. I used a FretRocker to locate the problem frets. It has four different straightedges to span any group of three frets, so it teeter-totters when it sits on a fret that’s taller than its neighbors. I found that the eleventh and the fourth frets had lifted up out of their slots a little. I swabbed a little silicone-free paste wax on the fretboard beside the loose frets. This keeps glue from sticking to the fretboard, so it chips away easily with a razor blade. After waxing the board, I put some water-thin #10 super glue under the frets. The glue bottle’s whip-tip puts the glue right where the fret meets the board. Thin, fresh super glue disappears down under the fret, pulled by capillary action. A clamp and a piece of plexiglass hold the frets down for a couple of minutes while the glue sets. Laying a straightedge on the frets showed that the strings were also buzzing against the last few frets up on the fingerboard extension. Hopefully, straightening the neck will make this go away. I’ll have to raise the bridge a little, because when the neck straightens the strings will be lower. A cam clamp grips the peghead, and my repair vise holds the cam clamp. The two red arrows show where I apply another clamp, using three wooden cauls and a wood crossbar. You can see that clamp in this photo: This rig gently bends the neck straight. By doing this before adjusting the truss rod, I save that skinny little rod from doing the hard work: it doesn't create the straightness, it just holds it in place. The truss rod’s adjusting nut has been mangled by somebody using a too-small hex wrench. Instead of a clean six-sided hex shape, the opening’s become rounded. And this nut is permanently attached to the rod—it’s not the kind that can be removed and replaced. If this were a 1/8" allen nut, there would be no problem: our Gripper truss rod wrench works with ruined 1/8" nuts. But this one’s too large for the Gripper. Maybe we need a complete set of Gripper wrenches. (Hey, that's a good idea! Watch for news in an upcoming Trade Secrets...) I degreased the damaged adjusting nut with alcohol and Qtips, then carefully tapped a truss rod wrench into it. I managed to tighten the nut just enough to hold the neck. Experience tells me I was lucky: this stripped nut isn't going to allow any more adjustments. I decided to do some future repairman a favor by rebuilding the nut using JB Weld from the home supply store. This is a hit-or-miss technique: sometimes it’s worked for me and other times... not so much. It's worth a shot. I held the mandolin vertically by mounting the repair vise sideways in a block of wood clamped to my bench. I super-cleaned the nut with Qtips and alcohol, then mixed up some JB Weld, a gray epoxy that hardens like metal. I waxed the Allen wrench, put it in place, and packed JB Weld around it. At least I think it did. I'm going to leave it alone rather than test it. The next person to work on this mandolin has a better starting point with this epoxy-supported truss rod nut than I had without it. All in all, I'd say this eBay auction turned out to be a good deal for my customer. (I didn't charge him for the JB Weld experiment on the truss rod nut.)Is this eBay mandolin a good deal?

This “eBaby” has problems:

Buzzing frets

Car wax, then super glue

About that warped neck

Here’s how I hold a mando for neck work

Mangled truss rod nut

It worked!