Guitar repair money talk: estimate hours, not dollars

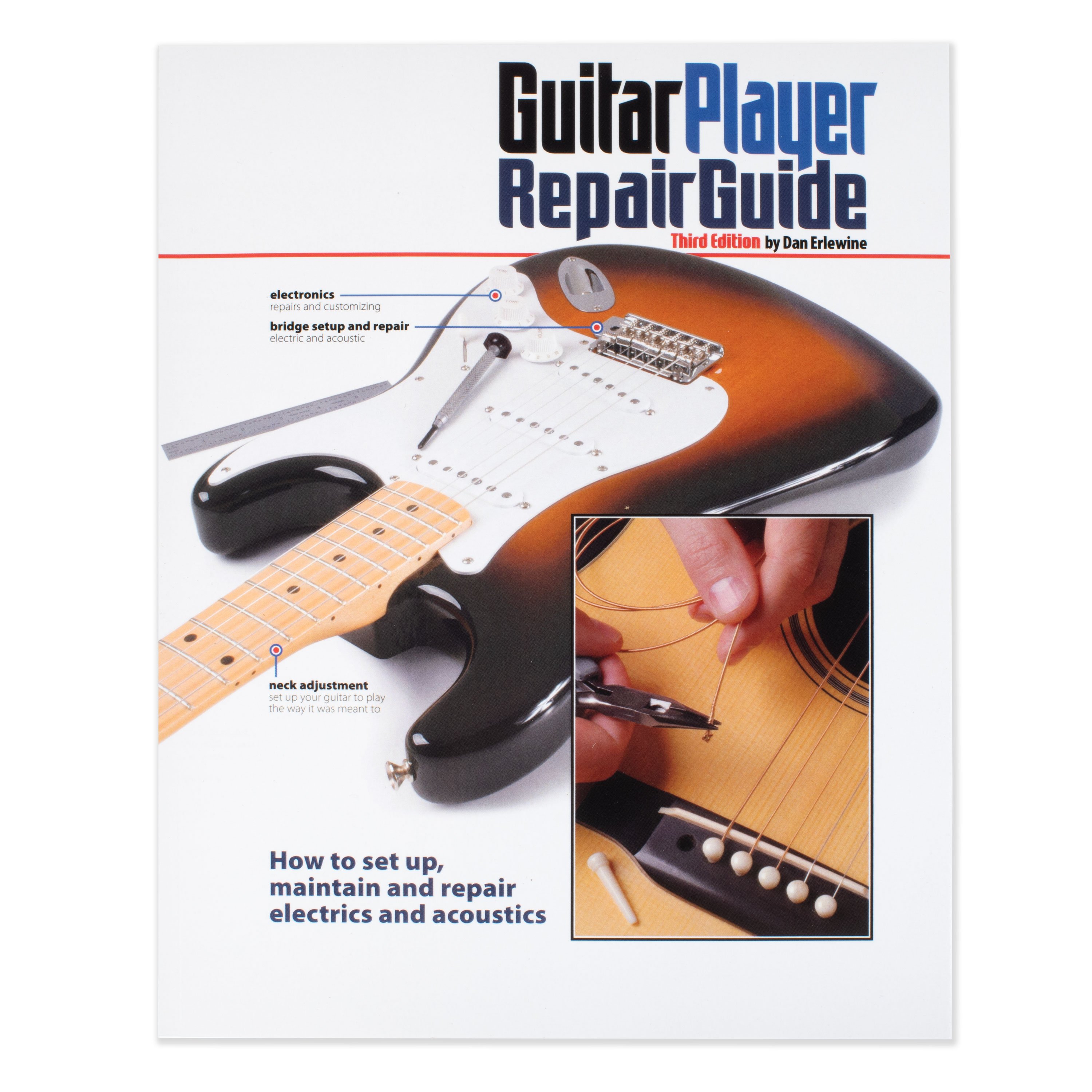

You don’t want to lose either one if you’re taking in repair work. But once you’ve made your start, if you want to stay in business, your prices have to cover the time you actually spend on the work — no matter what the guy down the street charges. You need to make accurate estimates of how much time a job will take you. To get good at estimating, try taking notes like I did on this job that came in last week: a 1945 Gibson J-45 flattop — kind of a rare one, since it’s all mahogany. To accurately estimate this job, I carefully thought through and wrote down every step of the work after talking with the customer: Dan, my old Gibson won’t play in tune, and the action’s too high. Yikes! Somebody’s put a classical bridge on it. So the saddle’s too tall... and it’s located wrong. And those worn-out frets are way too low. Whoever installed a classical bridge on this flattop didn't understand scale length and compensation, but you see all sorts of things in repair work. The guitar’s finish looked pretty beat, but the body was structurally sound. I put my notes, scribbles and sketches on an Acoustic Guitar Notes page — one of several computer-printable forms on the DVD included with my Guitar Player Repair Guide book. I also used the Repair Sheet, intended for listing prices. This sheet has a "Price" column but I don't list dollars there, I list estimated hours instead. I’ve made these two forms available to you for free at stewmac.com. Click the link to download them, print some copies and give them a try. Here’s how I filled out the Repair Sheet while planning this job: This estimate is subject to change The too-tall saddle on this bridge would cause high action all by itself, but this guitar’s frets were also worn out (only .022" high). A refret with taller frets is also part of the solution (higher fret tops = closer to the strings = lower action). The middle bridge in this picture is the new one I made from a bridge blank. I modeled it after an actual Gibson bridge shown on the left. On the right is the classical bridge someone had installed previously. Note that a classical bridge isn't angled for compensation, the way a flattop’s saddle needs to be. Can you install some vintage style tuners, too? Sure. I’ll even make them look like they’ve been on there since 1945! Bright new tuner knobs would look out of place on this old relic, so I used this trick I learned from my friend and neighbor, Gene Imbody of United Lutherie: Gently warm the white plastic tuner buttons with a heat gun. (Here I'm testing an individual button before I try this on the set of tuners.) This heating is something Gene discovered: it makes the plastic receptive to staining so color soaks in rather than sits on the surface. Any instrument. Any angle. Rock solid, and simply the best. Check it out! Mix ColorTone Vintage Amber stain with acetone, and apply it to the tuner buttons with an airbrush. After the buttons dry, buff them to remove excess color. You’ll wind up with ivory-yellow buttons that look like they’ve been oxidizing for years. Compare them to the new white ones in the photo below — a much better match for a guitar that’s showing its age! I didn’t forget to include the time for the tuners on my Repair Sheet estimate: So I'm up to 24-3/4 hours for this work. That’s a lot of time, and when you multiply that times your hourly rate, it’s going to be a big bill. This is the moment you’re tempted to think, “That’s too high — I'll bet I can do the work in fewer hours.” Try not to think that way! If you've overestimated your hours, the best way to learn that is to write down your time as you work, then compare your estimates with your actual time. You’ll quickly start doing better and better estimates this way. You can use your estimate list as a work order, too: show it to the customer beforehand so he can approve the estimate before you start racking up the hours. And how much to charge per hour? That's worthy of a whole issue by itself!Time and money.

In a previous Trade Secrets, I said a start-up repair business has to match prices with the competition.

Labor and parts estimate

Lowering the action:

Fixing the intonation:

Aging the tuners:

Ultimate Vise