Working with Carbon Fiber Reinforcement Materials

Information about the precautions related to, and the use of, Carbon Fiber Reinforcement Materials.

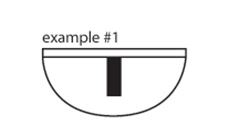

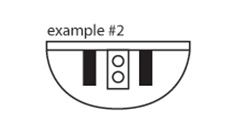

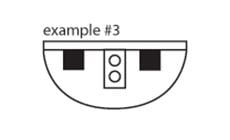

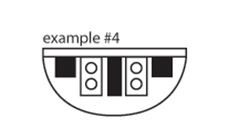

First and foremost, beware of splinters! We recommend wearing gloves when handling or cutting carbon fiber. The small splinters are very sharp, and quite brittle. This makes the splinters very difficult to remove since they often crumble and break as you try to extract them. As with most materials, the dust produced when cutting or machining carbon fiber is dangerous. Always wear a dust mask to keep the fine dust particles from entering your lungs and nasal passages. Safety glasses are also required whenever you are doing cutting operations. Carbon fiber is a very hard, brittle substance that will dull the cutting edges of your tools. If you simply need to shorten a piece of carbon fiber, we recommend using a hacksaw to cut it to the desired length. We DO NOT recommend using power tools to cut carbon fiber unless it is absolutely necessary. If you decide to use power tools to cut carbon fiber, use abrasive blades or wheels. Carbon fiber manufacturers use lasers or water-jet cutters. You can use Cyanoacrylates (superglue), epoxies, or wood glues. The primary use of carbon fiber in building and repairing stringed instruments is neck reinforcement. The design and dimensions of the neck, the truss rod (if there is one), and other aspects will help determine what piece of carbon fiber is suitable. You'll notice in the examples shown that the reinforcement rods are located away from the truss rod. This gives the neck greater stability and reduces twisting. Below are some typical examples and the carbon fiber used: Example #1: This is more of a repair situation, but could also be applied to a new neck which doesn't have a reinforcement rod. Remove the fingerboard from the instrument and rout a channel into the neck to accept the #4401 (1/8" x 3/8" x 18") reinforcement rod. Any of the recommended adhesives could be used in this or any of the following situations. Example #2 and #3: Here are two modern neck designs that use an adjustable truss rod and two reinforcing rods for rigidity and stability. The cross-sectional dimensions of the neck will determine whether example #2 or #3 is best suited for the instrument. Example #3 shows how a 5 or 6-string bass could be reinforced. Many of the thin, modern neck designs also require a set-up like example #3. Example #4: This is an approach primarily for 5 and 6-string basses where two truss rods are used in conjunction with three reinforcement rods. The two truss rods allow greater control over the neck, and help to control warping or twisting. The reinforcement rods make the neck much more rigid, while still allowing the truss rods to manipulate the neck as needed.Precautions

Machining

Gluing

Typical Uses