Repairing a broken-off tuner screw

Issue 181 January 03, 2013

In this Trade Secrets video, Dan Erlewine extracts and replaces a broken screw in a Fender peghead.

January 3, 2013 January 3, 2013In this Trade Secrets Video: Dan shows two ways he uses the Guitar Screw Rescue Kit. There are lots of screws on a guitar, and lots of places where this tool can save the day! Get this tool here at stewmac.com. |

|

|||||

Video Transcription

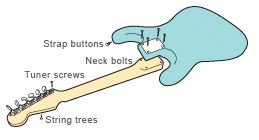

Dan Erlewine: I'm replacing a bent tuner for this guy and the screw shank that came off when he tried to get the tuners off. And I can remove that shank with this screw extractor. Now keep the extractor centered around that shank with the drill guide. And you can see down in there, and it's right on the money. There it is [Dan is holding the broken off tuner screw in his hand]. Now all I've got to do is cut a plug to fit that hole.

Cutting a plug with the plug cutter

A drill press is the best way to cut these plugs, but I can do it with the hand drill too, so I don't always bother with the drill press [Dan grabs the hand drill with the plug cutter bit in it and starts drilling]. You got to be steady, go slow and blow the chips out. There we go, a hard maple plug that matches the hole [Dan sets the plug into the hole and tamps it down with a fretting hammer]. I picked a pretty hard piece of maple and I'm just going to cut it down right now [on-screen text reads: Two Cherries Wood Chisels - Dans favorite wood chisels]. I waited about 10 minutes. It's probably not all the way dry. You can cut it when it's swollen up and shrinks down below, actually. I'll use the tuners to show me where to drill the new screw hole, right there. So that's the extractor and the plug cutter.

Drilling a hole to match the plugs

Now let's look at the drill bit. The 3/16s drill bit is to size a hole to match the plugs, and to drill holes out so you can plug them. It could be a strap button. In my case, it's the four mounting screw holes in this neck that a guy stripped out, and you use it with the guide blocks to keep you on center. [Dan puts glue then a wood plug into the peghead hole he drilled out] I'll trim this flush and drill a new hole.

Here's a tip: Using the extractor to cut tiny plugs

Now I'm going to let you in on a little secret. This is something I do with the tool that we didn't ever really had planned on. I used the extractor to cut really small plugs to plug small holes. Check this out.

I'm installing a set of Waverlys on this 1946, 00-18 Martin [on-screen text reads: Waverly Guitar Tuners at StewMac - Waverly tuners can't be beat], and it came to me with a set of Klusons on it from probably the '60s or '70s. It was built with a set of Waverlys that are totally different, and none of these holes line up. And I've got about 24 holes to patch on the back of this before I can get the new ones to fit.

There's your holes. Some of these were pretty big and wallowed out. I drilled them out with the drill bit and used the bigger plugs for them, 3/16ths. I think I have one more here and one more there to get. Then the little ones, I'm going to cut all those with my extractor. I made plugs down here on my mill drill. They're really accurate because the machine's heavy. I clamp the wood into the vice, crank the table along and cut out a plug, crank a quarter of an inch, cut out another one. And my mill drill has a reversing switch on the motor, which is important because these teeth cut in reverse on the extractor. I can do just about as good a job with an electric hand drill. I have to use the guide of course, otherwise it would jump all over.

You want to clamp the guide right along the edge of the board, and that leaves one side of the hole exposed a little bit and you still get your round dowel out of it, but the sawdust falls out and it keeps the bit cool. You can use the extractor to make tiny plugs that are 110 thousandths in diameter and they'll fit tight in a hole drilled with the Depth-stop Drill Bit that measures 109, the black one. I probably didn't use to look forward to a job like this as much as I do now. And now it's actually fast and fun, and accurate.