Wet-sand before buffing

When, why, and how to wet-sand.

IN THIS ARTICLE

| • Why you should wet-sand your instrument before buffing • What to use for wet-sanding • How to wet-sand |

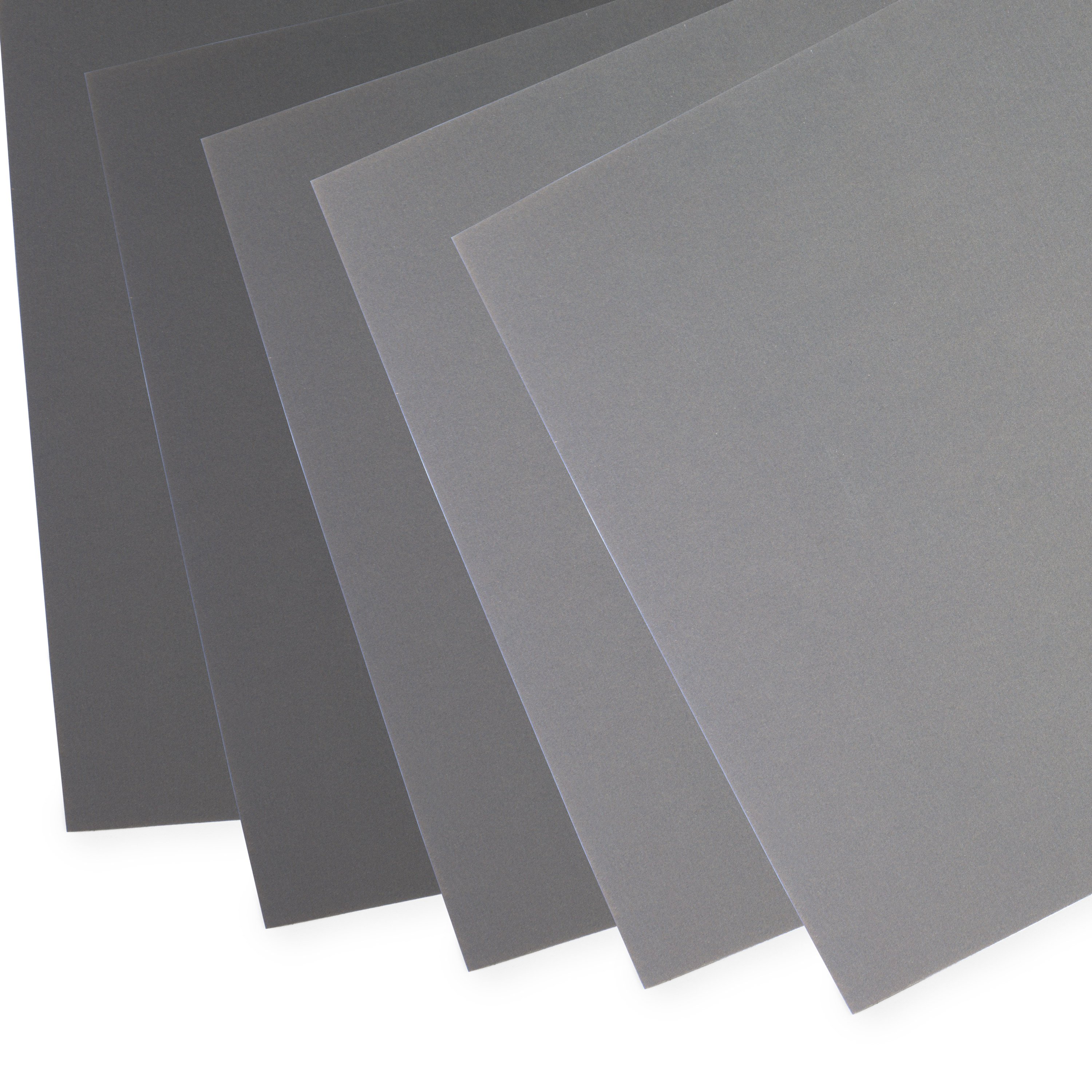

Once the final lacquer coats have cured, most finishers begin wet-sanding with fine-grit finishing papers. You want to remove the "orange peel" texture before buffing (see picture). Even high quality finishing papers will build up quickly when used dry. Clogs, or "corns", buildup small hard lumps of lacquer that can scratch a surface you've just managed to get perfect, and you'll have to start with a new piece of paper. Wet-sanding lubricates the surface, washing out any grit-clogging particles and reduces the heat of sanding. Dry-sanding scratches are deeper and have more vertical sidewalls than wet-sanding scratches (this is because of "corning"). Wet-sanding scratches may be as deep but they're not as obvious because the edges of the scratch are more rounded. Therefore, wet-sanded surfaces are easier to buff, and the final appearance will not show the super-fine scratches. Many different liquids can be used in

wet-sanding, here are some popular examples: Water is a great choice. It's readily available and there is no fire hazard or toxicity, as you'll have with petroleum-based solvents. Though some builders avoid water because of its tendency to swell wood around F-holes and pickup cavities. When wet, exposed endgrain can cause the lacquer to lift around holes. Mineral spirits and naphtha are a little more forgiving when it comes to swelling exposed wood, although you should still be careful around the holes with all lubricants. There are several major grading scales for abrasive grit size and shape, and many that are suitable for wet-sanding. We recommend "P-scale" graded papers. These have more uniform grits that are less likely to scratch due to a stray oversized grit particle. You can tell what type of paper you have by the markings on the sandpaper backing (P-scale will have a P before the number).

Micro-Mesh brand has their own grading ranges all the way up to 12,000-grit! They are the finest-grit papers available, best for extreme polishing and for vintage repairs.

Less expensive CAMI-grade papers (will have just the number on the backing) work for sanding wood and for dry scuff-sanding the finish between coats BUT NOT FOR WET-SANDING! Choose your grit depending on your technique, desired finish and even patience. When you wet sand to 800-grit, then you should start buffing with a coarse polishing compound. If wet sanded to 1200-1500 grit start, with medium compound. (In both cases proceed through all buffing stages.)

Use 1500 and 2000-grits for ultra-delicate sanding. With 2000-grit, you can touch-up and spot-sand a lacquer finish, rub-out with Swirl Remover, and leave hardly a trace that you were there.

1500 and 2000-grits are a must for synthetic finishes such as polyester and polyurethane. Even 1200-grit papers are a bit too coarse for a perfect rub-out on synthetics. (Ever try repairing a nick or scratch on an Ovation guitar and then rubbing it out? With 2000-grit, you'll be able to do it!) Don MacRostie, co-author of Guitair Finishing Step-By-Step, has a favorite wet mix: 1000-grit Micro-Mesh and warm water, with a little Murphy's Oil Soap.

Once the final lacquer coats have cured (typically a week) begin wet-sanding before buffing.

Soak finishing paper overnight.

Wet-sand cured finishes starting with as fine a grit as possible.

Use a piece of paper about two to four inches square. Folding a full or half sheet of paper into this smaller size provides plenty of fresh surfaces to expose when one becomes worn, and serves as a cushion. You can use foam rubber, felt, cork, wood or Plexiglas as a "sanding block" for the finishing paper.

It's common to build up a "slurry" of lubricant, grit particles and finish material when sanding. Every minute or so, remove this with a clean cloth.

Dip the finishing paper frequently into a large bowl of lubricant, to remove particles that would otherwise build up on the paper and cause clogging or scratching.

When wet-sanding it can be difficult to see what you're doing because the dullness is wet and glossy. Wet-sand for a while then dry it all off. Observe where you need to sand more, then go to it.

Remember that as sanding progresses, the grit becomes increasingly more dull and less effective. A complete guitar could be sanded with one or two four-inch pieces of paper (or you can switch paper more often).WHY YOU SHOULD WET-SAND BEFORE BUFFING

1. Everybody does it.

2. If you dry sand, you ruin your fine finishing paper in 10 seconds.

3. Better scratches. Huh?

WHAT TO USE FOR WET-SANDING

All grits are not created equal

HOW TO WET-SAND