How and why to mix fresh shellac

Dan Erlewine shares his experience working with, and knowledge of, shellac.

IN THIS ARTICLE

| • Intro from Dan Erlewine • Dewaxed vs waxed • Thinning ratios | • Storage • Advantages & disadvantages of shellac • How to mix shellac, step-by-step |

"On the rare occasions that I refinish a guitar, it's usually during a serious structural restoration—in one case a 1958 Gibson ES-5 that was severely burned in a fire—I mix a batch of fresh shellac the day before I start to spray. I don't mix it until all the wood preparation is finished. Our book Finishing Step-By-Step details shellac's desirable qualities. Here are two excerpts from that book—first a description of shellac with its advantages and disadvantages, followed by instructions for mixing fresh shellac (taken from the "recipe" chapter at the end of the book): Dewaxed shellac makes an excellent sealer over stains and under lacquer (helps keep fisheye-causing contaminates out of topcoats, too) and is useful for finish repairs and touchups. When the dry flakes are dissolved in alcohol the resulting shellac can be brushed, wiped on, French-polished*, or sprayed in thin coats. Shellac has good clarity and compatibility with most finishes, is easy to rub out, and easy to repair with additional shellac. Waxy shellac is excellent when the finish will be only shellac (as in a French polish finish*). Amber in color, it adds a bit more moisture resistance and flexibility to the final finish. It contains none of the shelf-life additives found in ready-mixed shellacs that can be unsuitable for French polishing. Apply by hand, using a padded cloth.

*Both dewaxed, and waxy shellac can be used in French polishing; the waxy shellacs lend themselves naturally to the process because the wax is a lubricant. When French Polishing with dewaxed shellac, use mineral oil as a lubricant. The term "cut" is used when referring to the amount of alcohol added to dry shellac flakes to dissolve them (one pound of shellac flakes dissolved in one gallon of alcohol gives a well-thinned one-pound cut). Store-bought shellac is usually sold in a heavier three- to four-pound cut, and then thinned accordingly. (Four pounds of shellac flakes thinned with one gallon of alcohol produce a four-pound-cut shellac.) Common shellac thinning ratios range from a two- to a five-pound cut.

Use this chart to mix the desired amount of shellac:

In a properly labeled glass jar (do not use metal or plastic), measure the desired amount of dry shellac. Pour in Behkol solvent or denatured alcohol and set the mixture aside to dissolve. Shake the jar frequently to prevent a lump of shellac from forming in the bottom. Allow ample time for the shellac to dissolve. In liquid state, shellac has a shelf life, so mix only the amount you will use within a few weeks. Once shellac flakes are mixed with alcohol, the mixture has a shelf life of no more than a year and a half. However, most of us discard shellac if it's more than two months old! Keeping it cool will increase mixed shellac's shelf life. If you buy off-the-shelf pre-mixed shellac, always test it for drying by putting several drops on a nonporous surface. Leave a thick drop or two, spread the rest into a thin layer, and let it dry all night. By the next day, the thin layer should be dry and sandable. The thicker drop shouldn't easily take an imprint from your thumbnail. If it does, it may be usable but questionable—give it another day or two of test-drying before using it. Advantage Disadvantages Many finishers keep fresh-mixed shellac on hand for a variety of projects, including French polishing, sealing, wash coating, and touching up. With shellac, fresh is somewhere between two and six months, at which time we throw it out and mix a new (small) batch—a pint or two of shellac in a four-pound cut will go a long way.

Start with fresh shellac flakes. If the flakes are fresh they'll dissolve overnight. If they aren't dissolved in four days, consider discarding your batch and getting new flakes, especially if the mixture doesn't dry when you test it on scrap. Here's an easy way to mix shellac to the cut we use. Into a clear glass jar with a tight-fitting lid, pour an arbitrary amount of dry flakes and shake them down so they settle. Pour in denatured alcohol until the flakes are immersed and there's between a half-inch to an inch of liquid remaining on top the flakes. This produces a thick shellac in about a four-pound cut that can be thinned as needed for brushing, French polishing, or spraying. Shake and stir the mixture occasionally to keep it from forming a mound of thick, undissolved shellac at the bottom of the jar. Also, you can warm it gently, such as with the indirect heat from a desk lamp, to speed the dissolving process. Our shellac is fresh and will generally go into solution overnight.

Store shellac, mixed or dry, in a cool dark place. Besides being the best sealer coat, shellac gave the body of this otherwise very white-looking spruce and maple guitar the golden quality it needed to match the neck which did not get refinished. This photo represents the true color of the shellac and how it matched the neck's original finish. The white neck represents exactly how the stripped and sanded body looked before the shellac was applied. I will use shellac to finish the two sides of the peghead which were burned beyond saving—just like the tuning keys you see here. The rest of the fire damaged finish on the neck, including the front and back of the peghead, I was able to wet-sand and rub out.

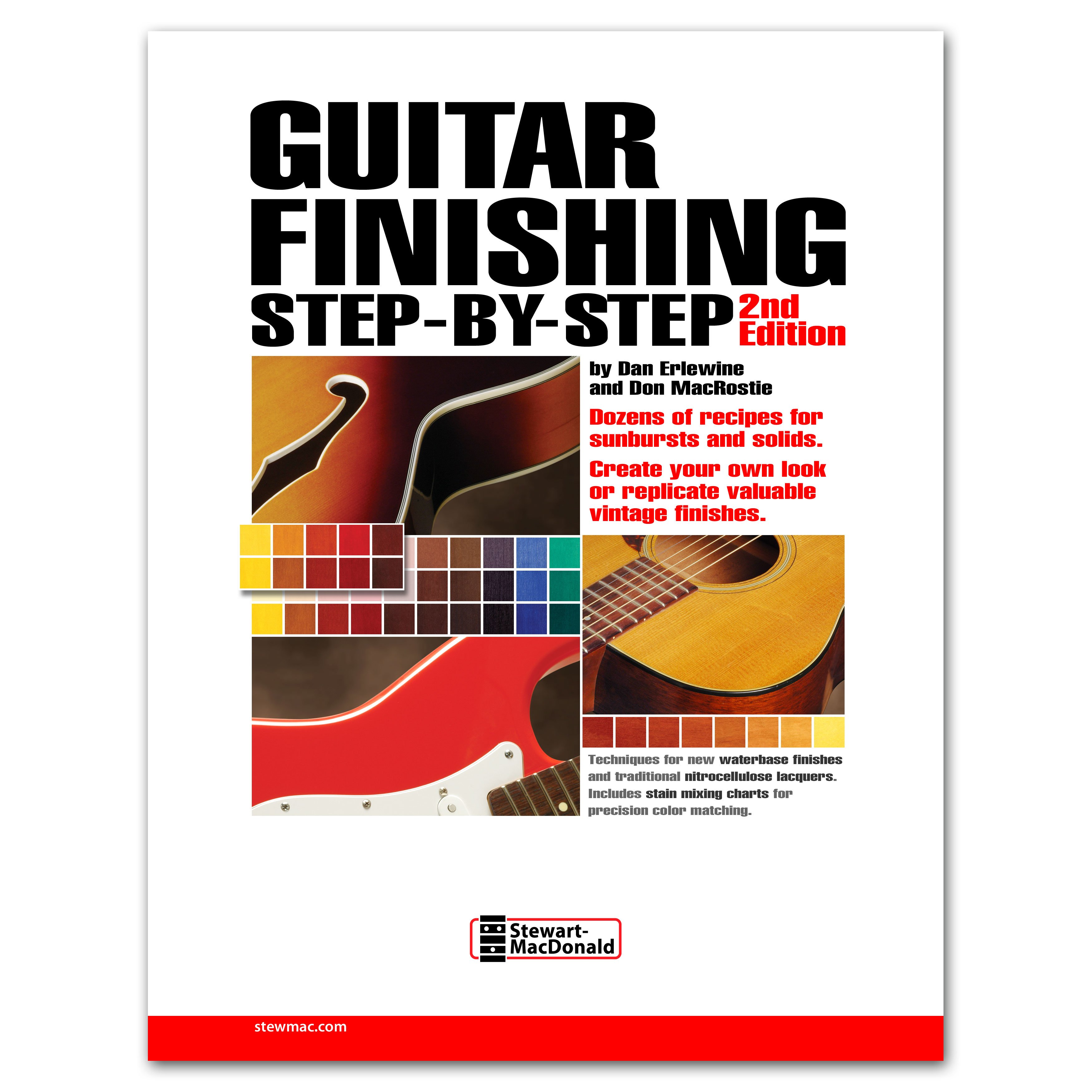

—Dan Erlewine This information on shellac is just a sampling of the material covered in Finishing Step-By-Step.

This expanded 2nd edition features color stain mixing charts, a color gallery of vintage finishes, and detailed recipes for recreating them with professional results. $29.95 Buy NowINTRO FROM DAN

DEWAXED VS WAXED

THINNING RATIOS

1-lb cut

1.5-lb cut

2-lb cut

3-lb cut

Behkol solvent

16.0 oz

24.0 oz

32.0 oz

48.0 oz

1 gallon / 128 oz

8.0 oz

12.0 oz

16.0 oz

24.0 oz

2 quart / 64 oz

4.0 oz

6.0 oz

8.0 oz

12.0 oz

1 quart / 32 oz

2.0 oz

3.0 oz

4.0 oz

6.0 oz

1 pint / 16 oz

1.0 oz

1.5 oz

2.0 oz

3.0 oz

1 cup / 8oz

0.5 oz

0.75 oz

1.0 oz

1.5 oz

1/2 cup / 4 oz

STORAGE

ADVANTAGES & DISADVANTAGES OF SHELLAC

RECIPE FOR FRESH SHELLAC

Start fresh!