Soldering

The do's and don'ts of soldering.

This photo illustrates the wrong way to wire a guitar! Thanks to Les Schatten for forwarding this amazing wiring disaster that came into his shop in Kitchener, Ontario, Canada.

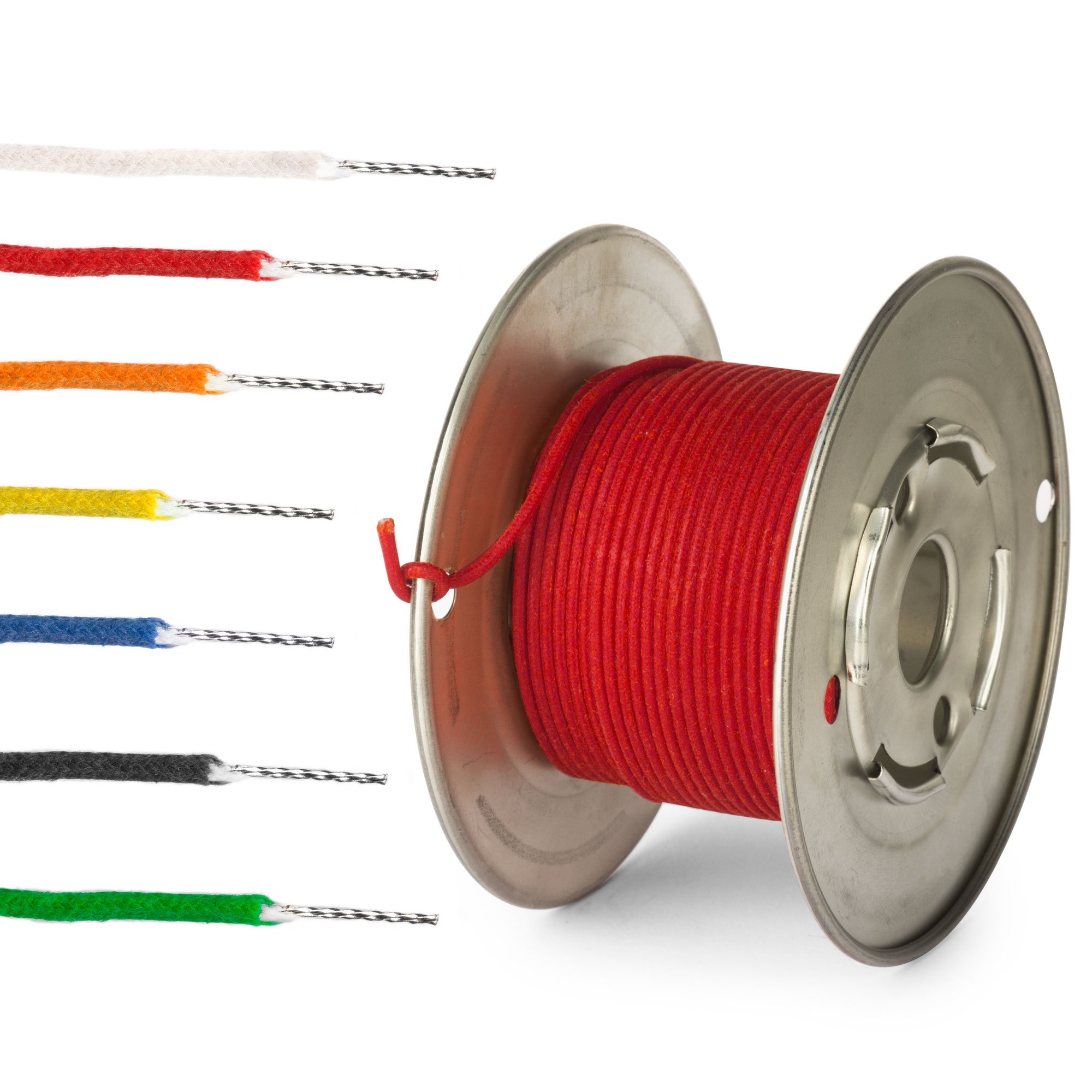

Before you start soldering, you need to get a feel for it. It's 85% technique; 15% materials and equipment. You don't have to spend a bunch of money on soldering equipment for a successful job. High-priced soldering irons are designed for professionals who use them daily. An inexpensive 40-watt soldering pencil will do just fine. The more experienced you are with your soldering pencil, the better your wiring project will turn out. Don't blow on a solder joint to make it harden faster. This can cause air pockets within the joint that can corrode or loosen it over time—a "cold solder joint." Don't strip too much insulation from a wire, unless you want a potential troubleshooting nightmare. Just expose enough wire for soldering, usually 1/16" to 1/8". Too much exposed wire can contact ground wires, shielded pickup wires, or "hot" wires. Do use rosin-core solder! Standard 60/40 rosin-core is best, and we prefer smaller .032"-.062" diameters for guitar wiring. Do "tin" the wire and the soldering points before soldering the joint. This doesn't mean applying a huge glob of solder; just a very thin pre-coating will do. Do apply heat to the connection first, then apply the solder and let it flow over the joint. This also helps prevent cold solder joints. Do "tin" a new tip. When breaking in a new soldering iron or tip, tin the tip as soon as it gets hot enough to melt the solder for the first time. Flow the solder over the contact surfaces of the tip, and let it set for about ten seconds or so. Wipe the excess onto a damp sponge and apply more solder. Repeat this process several times during the first few minutes of its life, and your soldering tip will last longer and conduct heat better. Do use a soldering stand to hold your soldering iron, so you won't burn yourself or your guitar. A soldering stand usually has a sponge holder for cleaning the tip. Do plan the wiring ahead of time, to avoid soldering under an existing wire. Be sure the wires are long enough to allow removal of the pickguard or control plate for inspection without desoldering.