Pickup winder from Down Under

Kevin O'Brien introduces his homemade pickup winder.

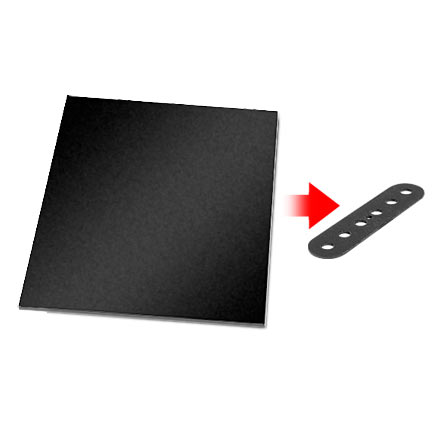

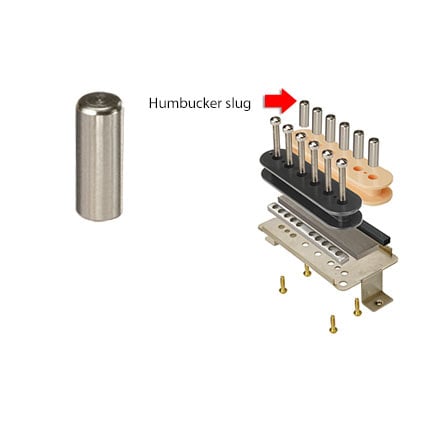

Kevin O'Brien credits Gary Brawer and Lindy Fralin for inspiring him to build the pickup winder you see here. Says Kevin: "This machine, for all its peculiarity, winds beautifully with lots of control, and the gentle torque reminiscent of an old steam engine." A footbrake (below) can slow, or stop instantly, the treadle-operated flywheel (right pedal) without breaking the wire. Note the adjustable hand rest (black walnut), and mechanical counter. The white acrylic back screen is an "eyesaver," and the vertical nylon fingers are "limiters" to keep the hand-traversed wire on course. The thin drilled wooden plates on top of the machine are used as spacers when Kevin mounts the bobbin holder (thick wood blocks w/beveled edges in the photos) for winding. "If I add a spacer and mount the bobbin's top plate to the bobbin holder," writes Kevin, "I get a clockwise wind. If I mount the bobbin's bottom plate to the bobbin holder without the spacer, I get a counterclockwise wind. The spacer's only purpose is to compensate for the projecting magnets at the top plate and hold them captive. A center screw holds everything in place, and a catchplate on the side of the bobbin holder grabs the bobbin and stops it from free-spinning." "How many times have you wired a pickup and found that it's magnetically out of phase, even though the white and black leads looked right?" Jim Rolph, of J.M. Rolph Pickups introduced us to the benefits of a magnet polarity tester.

Next: Magnet polarity