Parts Kit for Precision Bass Pickups

Assembly instructions for the Precision bass pickup kit.

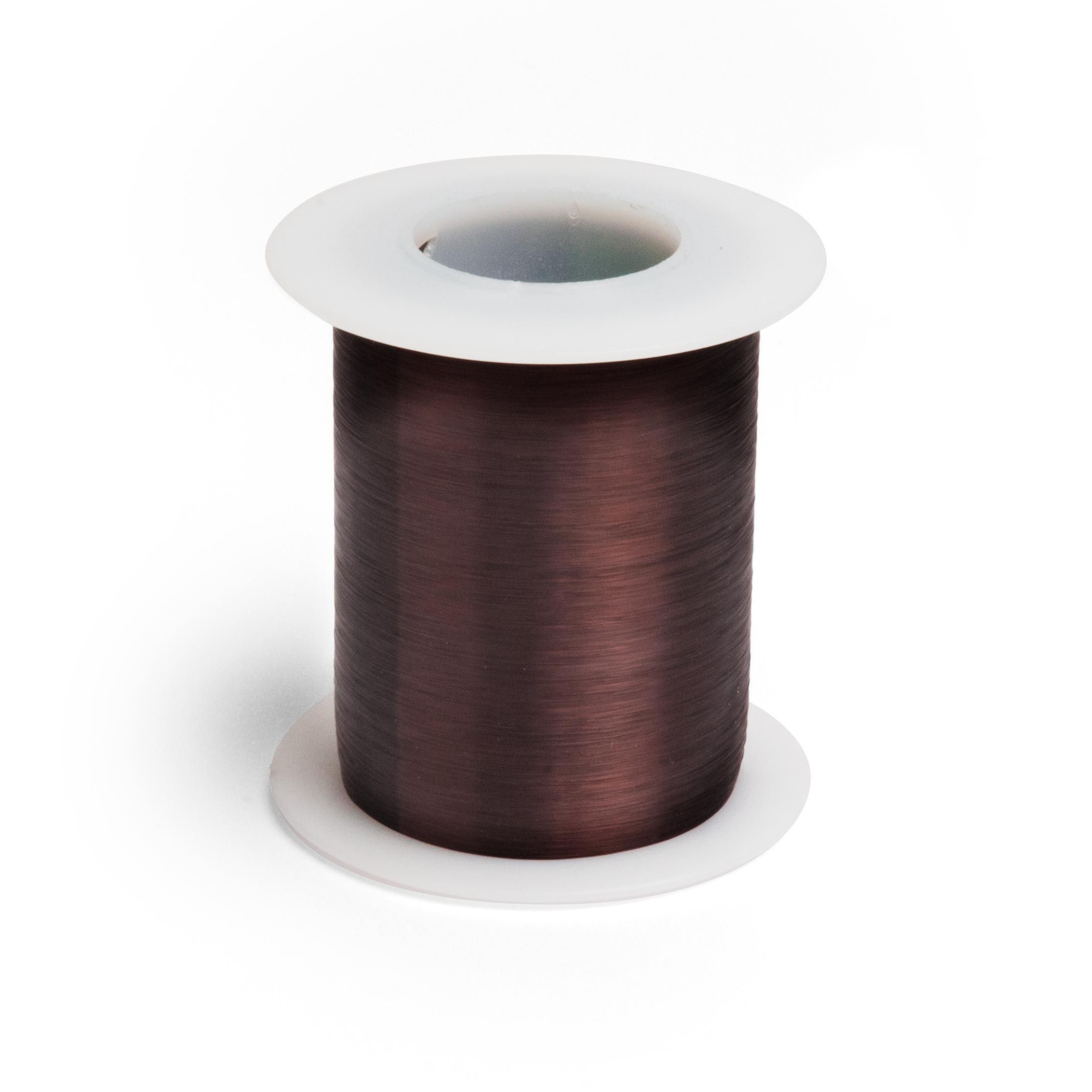

Smooth, and slightly round the edges of the fiber flatwork with very fine sandpaper to remove any roughness that might catch the thin wire during winding. On the bottom piece, countersink the underside of the hole, to better fit the eyelet and allow it to expand and grip more securely. Insert the eyelet into the underside of the flatwork. The small end of the eyelet will be facing up for setting. Setting the eyelet curls and spreads the brass, creating a flange that grips the flatwork. Before setting, back up the eyelet with a solid surface such as aluminum or steel. (Wood is too soft to provide a proper backup.) We highly recommend the Eyelet Setting Tool for a clean, consistent installation. To hold the polepieces upright while installing them, make a small jig with a hole just larger than the polepieces. Drill a 19/64" hole through a short length of hardwood or acrylic, 1/4" thick x 3/8" wide. An accurately drilled hole will hold the polepieces squarely and keep your fingers out of the way when pressing or tapping the pieces into the flatwork. Option 1: Using a small hammer (one with a plastic or brass head, like a fret hammer, is the most gentle), firmly tap in the magnets while the flatwork rests on a support block placed on a very solid, flat surface. Option 2: Press the polepieces into the flatwork using a drill press. Close the jaws in the drill press chuck and use the flat underside of the chuck as an overhead press. The thickness of the eyelets in the bottom flatwork will keep it from laying flush to the work surface, so let them hang over the edge of a support block during installation. Once they're installed, make sure the polepieces are square to the flatwork and parallel with each other. If they're not, or if the flatwork is warping, manipulate the pieces until the poles are squarely seated and the fiber pieces are flat. Pieces of hardwood placed on each side of the polepieces will serve as spacers to make sure the top flatwork is at the right height, leaving a gap of 1/4" for the wire. Cut two pieces measuring 1-1/4" x 1/4" x 1/8". Use a rubber band to hold them in place beside the polepieces (photo). Option 1: Tap the top piece on with your hammer, using the polepiece holder you made as a caul to protect the flatwork as shown in the photo. Option 2: The drill press can be used again to provide downward pressure. A small socket wrench or similar shape held in the drill press chuck can provide a caul to press the flatwork onto the polepieces. Start on the two centermost polepieces. Alternate between them, applying pressure (or tapping) until the flatwork is started over both pieces. Again, the flatwork may warp out of shape slightly—keep this to a minimum by frequently alternating, pressing or tapping each hole equally. As the poles start to come through the top of the flatwork, your polepiece holder will become helpful in tapping the flatwork down. When all the magnets have started through the holes, be sure to have your two wooden spacers in place. The top flatwork is installed when it is flush against these two spacers. The spacers should be snug when you're finished, but will pull out with little trouble. Fender uses 42AWG (American Wire Gauge) on Precision® Bass pickups. There are lots of ways to wind a pickup. Virtually anything that spins with a controllable speed could be rigged to do the job (you can see a winder made of Lego's on YouTube!). But it's easier and more accurate to use the Schatten Pickup Winder, with digital counter and speed control. We use this winder in our shops and in the following photos. The number of winds, the coil wire tension, and the way in which you build up the layers of wire all affect the tone of your pickup. Don't make the winds too tight, or you could cause the pickup to deform from the pressure. If your winds are too loose, you could have problems with excessive feedback. Precision Bass pickups are wound with approximately 10,000 turns of wire. If you don't have a counter, you can start by looking at another pickup and visually matching the size of its coil. You can also tweak the number of windings for a custom sound. For example, winding a coil 5% under spec can give you a sound that is brighter while overwinding by the same amount can give you a warmer sound with less top end. Another thing to keep in mind is that Precision Bass coils are reverse wound with reverse polarity, to make the pair hum canceling. This means one coil is wound clockwise (when viewed from the top of the pickup) with its magnets charged South up, while the other is wound counterclockwise with its magnets charged North up. Attach the pickup to your winder. Depending on the winder, this might mean using double-stick tape (carpet installation tape is strong) or another fastener. Carefully center the pickup square to the winding shaft. If your winder has a flat pickup mounting plate, the metal eyelets on the underside of the pickup will keep the flatwork from sitting flat on the surface. Multiple layers of double-stick tape can shim it up while holding it, or you may want to file a groove into the mounting plate to accommodate the thickness of the eyelets. If you have a winder with a counter, set it to zero. Start the first 6-10 wraps turning the drill winder by hand, to be insure that the coil wire won't be pulled off the bobbin when you start the winding. Coil wire is thin and easy to break! Control your winding pressure, and the drag on the wire, by folding a piece of felt over the wire as you hold it. Talcum powder on your hand is another way to keep a light hold on the wire without sticking. If you break the wire you can choose to start over or you can sand the insulation off the wire ends and solder them back together. When you're done winding, cut the coil wire. Leave enough to reach the eyelets with at least 2" to spare. Sand the coating from the end of the wire and wrap it through the treble-side eyelet. The start and finish ends leading to the eyelets should be snug and flat against the bottom flatwork. This crafty example demonstrates that you can wind a pickup with very simple gear. It's economical, although it has no way to count the number of winds. Clamp an electric hand drill to a workbench. The speed control is simply a second clamp which is tightened onto the drill trigger: screwing it down tighter presses the trigger and speeds up the drill. We fashioned a mounting plate in the shape of the pickup (with a recess for the eyelets), and mounted that onto a metal shaft that's held in the drill chuck. Whatever your method, see that the pickup is spinning true and straight. You'll be moving the wire back and forth as it feeds onto the coil, and you'll want to create a "traverse limiter" to keep it between the two flatwork pieces. On the Schatten Winder, this is a polished metal rod with adjustable right and left limiters. For this simple winder, the limiter is a hole drilled in a piece of wood that pivots right and left. The hole must be sanded very smooth. Since the two P-Bass coils are joined together to make a single unit, it is easier to charge the polepieces before connecting them together. The polepieces are now ready to be magnetized. Pass them between two strong magnets held apart with just enough room to pass the pickup between. Remember, Precision Bass magnets are traditionally reverse-wound, reverse-polarity so make sure you charge one coil opposite of the other. If you want the tops of the pickup poles to be South up, the bottoms of the poles must pass over the South magnet, with the tops of the poles actually passing over the North. You can make a simple fixture using a basic C-clamp. Remove the foot with a screwdriver and attach two of our 1" diameter Guitar Repair Magnets with #20 super glue. Orient the magnets so that they pull toward each other, and adjust the magnets so the pickup fits just between them. Identify and mark the north/south polarity for reference. You can then clamp the fixture into a bench vise as a nice holder while charging. Our Nut and Saddle Vise makes for a sturdy charging station. Since the jaws are steel, the Guitar Repair Magnets hold themselves in place without glue. This lets you adjust for different pickups and different proximity by simply opening and closing the vise. The Guitar Repair Magnets will charge the Alnico 5 magnets to their full capacity of 20-25 Gauss. Several passes through the magnets does the job; move the pickup as slowly as you can while keeping it free of the magnets. To determine a magnet's strength, we recommend the analog Model 25 Magnetometer (50-0-50 gauss range) available from the R.B. Annis Company. It works well and is reasonably priced. From the underside of the pickup, feed the black and white hookup wires through the eyelets. Push back the covering, exposing approximately 3/16" of the lead wires and carefully feed them down into the eyelets on the bottom of the pickup. Solder each wire to its eyelet and coil wire. The black wire will be soldered to the start of the clockwise South up coil and the short white wire will be soldered to the finish. Solder the white wire to the finish of the counterclockwise North coil. Again, this process is easier when done before connecting the two coils together. Potting a pickup (dipping it in melted wax or other material) helps eliminate unwanted microphonics and feedback. Most Fender pickups were potted with lacquer or wax. Although some pickups weren't potted at all, potting's generally a good idea. Refer to our instruction sheet, Winding Pickups with the Schatten Pickup Winder, for information on potting materials and techniques. Connect the short white wire from the finish of the clockwise South-up coil to the start of the counterclockwise North-up coil. Test with a volt/ohm meter set to the 20K range. The pair should read around 10.5K. If you get an open circuit: are your connections to the coil wire good? Did you solder a break inside the coil which is now causing a short?Prepare the flatwork

Install the polepieces

Install the top flatwork

Wind the coil

Homemade hand drill pickup winder

(single-coil pickup shown in our photos)

Charge the magnets

Soldering the lead wires

Pickup potting

Connecting the coils

Tests the DC resistance