None of your beeswax? Potting pickups with paraffin.

Bye bye, beeswax

Wax-potting pickups using paraffin only

Customers ask us about wax-potting pickups: why to do it, how to do it, and which wax to use.

For years, we’ve answered these questions with an online article about how the great pickup maker, Lindy Fralin, does it. Described in that story is Lindy’s recipe for potting wax: 80% paraffin and 20% beeswax.

But the other day a customer emailed to say “Hey StewMac! Lindy doesn’t use beeswax anymore — he uses candle wax.” When I heard that, I called Lindy to get an update.

It turns out Lindy’s done some new research, with the result that he no longer uses beeswax at all. He’s switched to paraffin, the petroleum-based wax sold in the supermarket for making candles and sealing jelly jars. He likes the fact that paraffin melts at a lower temperature, so there’s less of a chance of a coil being damaged by heat.

What is wax potting?

If the sound of your guitar vibrates the coil wire or anything loose inside a pickup, you’ll get microphonic feedback. The usual way to prevent this is to drench the pickup in a pot of melted wax to dampen vibrations. Some pickups are potted in other materials, and a few are not potted at all.

Lindy’s other reason for ditching beeswax surprised me:

He says beeswax darkens the tone of his pickups, affecting the sound in a way he doesn’t like. With paraffin, he hears a clearer tone with better highs than what he heard when using a mixture of the two. That’s interesting new information. Thanks, Lindy!

A student training here in the shop, Jeff, was rewinding a few vintage pickups that needed repair — perfect timing for photos of pickup potting.

The first one Jeff rewound was this vintage jazz bass pickup. He decided to go with the traditional mix of paraffin and beeswax. After all, if the the beeswax does add some bassiness and loses some highs, that’ll be a good fit for a bass, right?

Does beeswax sound sweeter to you?

You won’t find a better pickup-winding expert than Lindy Fralin. But when it comes to guitar tone, what one player avoids is what somebody else wants most. If beeswax introduces some sort of dampening for a darker “beeswax tone,” that might be exactly what you’re after.

I don’t do a ton of pickup winding in the shop, so I don’t have a full time wax melting pot. I use my glue pot set up as a double boiler, with a jar of wax surrounded by hot water for potting pickups.

It’s the perfect size for single pickups or small batches. The glass jar acts as an insulator of sorts, further protecting the pickup from damage caused by heat.

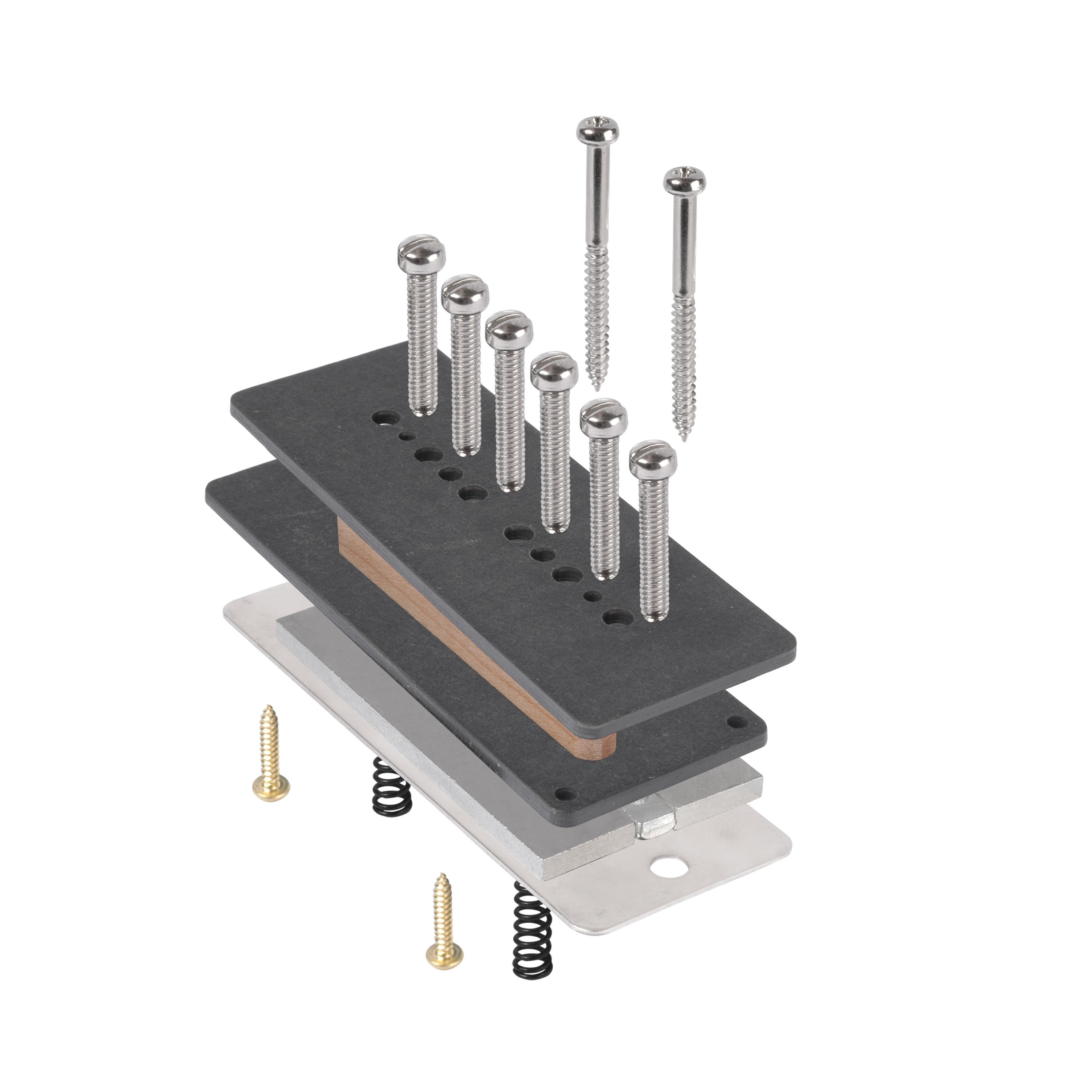

The glue pot was designed specifically to heat hide glue to 150°F. This temperature’s okay for potting most fiber or plastic bobbins without damaging them, but a better temperature for wax would be 140° (Lindy Fralin heats potting wax to 140°-145°). To be on the safe side, Jeff dialed back the adjustable thermostat concealed inside the glue pot. Here’s how that’s done:

With the glue pot unplugged, remove the two screws holding the heating pan and pull it out to expose the rheostat underneath. Mark the end of the adjustment shaft so you can return the pot to this factory setting later. With a small wrench, slightly back off the rheostat just a little. Re-assemble the pot before plugging it back in.

Testing with a thermometer, the temperature wasn’t exactly right, so Jeff disassembled and adjusted the pot again. It took him two tries to nail the desired temp.

With the wax melted at 140 degrees, it’s time to dunk the pickup. Watch for air bubbles rising to the top. When they stop coming out of the coil, it’s a good indication that it’s saturated. This usually takes about 15-20 minutes.

Let the excess wax drain into the jar, then place the coil on a paper towel to further drain and cool. Carefully pat off any excess wax as it cools.

For these pickups, Jeff decided to give pure paraffin a try. A petroleum product, paraffin and its vapors are quite flammable, so we watched the temperature closely using this kitchen thermometer. I know a few guys who use digital models with great results, too.

Okay, let’s try paraffin on an uncovered humbucker

Next up is a set of Parsons Street humbuckers that a customer wanted potted. Like the original 1950s PAF humbuckers, Parson Streets are unpotted. But my customer’s a high gain/high volume player that really needs his pickups potted for better control over feedback in live performance.

Never use a microwave, stove or hot plate to heat wax!

There’s too much risk of fire. Adjustable crock pots and deep fryers will do the job, but monitor the temperature continuously with a thermometer.

My customer leaves the cover off one of his pickups to give it less capacitance. (Capacitance refers to the tendency to lose high frequencies when the signal is in close proximity to a metal ground.) Since there was no cover, Jeff put a rubber band around the coil-covering tape so it wouldn’t come loose in the hot wax.

After the pickup is potted, the rubber band comes back off.

Covered humbuckers

One cause of feedback is the metal-on-metal contact between a humbucker’s cover, polepiece screws and coil slugs, so it’s important to dampen all of these potential vibration points. Lindy Fralin gave us a great tip for potting covered pickups:

1. Lower the polepiece screws until they’re below the cover surface, then cover the holes with masking tape.

2. Pot the pickup, then let the excess wax drain briefly: only about 15-20 seconds.

Lay the pickup face-down to cool. The wax inside will pool around the pole screws, sealing any gaps between them and the cover and bobbins.

After it’s cooled, return the screws to their normal heights and wipe the excess wax off the outside. Use something soft, like a suede buffing cloth, so you don’t scratch the cover — even paper towels can leave fine scratches in the plating.

Here’s Jeff with the pickups he just potted, and the waxes he used.