Eyelet Setting Tool and Bit Instructions

How to use the Eyelet Setting Tool and Bit set to install eyelets in flatwork.

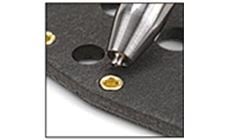

The Eyelet Setting Tool lets you install mini eyelets in pickup flatwork with clean, professional results. This custom steel stamp comes with a .073" (1.85mm)diameter steel bit for drilling the correct size mounting holes. The drill bit is sized to provide a snug fit, holding the eyelet in place for setting. Using a drill press will ensure that the holes you drill are perpendicular. Mark the location for the hole with a centerpunch. The indentation helps keep the drill bit from wandering as you start to drill. Back up the flatwork with a smooth piece of hardwood and drill slowly, letting the drill bit do the work. This reduces tearout as the bit cuts through the bottom of the flatwork. Clear the holes and shave away any burrs with a razor blade or X-Acto knife. Lightly countersink the underside of the hole, to better fit the eyelet and allow it to expand and grip more securely. Insert the eyelet into the underside of the flatwork. The small end of the eyelet will be facing up for setting. Setting the eyelet curls and spreads the brass tube, creating a flange that grips the flatwork. Before setting, back up the eyelet with a solid surface such as aluminum or steel. (Wood is too soft to provide a proper backup.) Place the tip of the Setting Tool into the eyelet, carefully holding it perpendicular to the flatwork. Set the eyelet with a few short, sharp blows from a hammer. Rotate the Setting Tool with each hammer blow. For better consistency and professional results, use your drill press to apply the setting pressure. Chuck the Setting Tool into the drill press and leave the press turned off (you will be using it as a press only, not as a drill). Lower the press in small increments until you've rolled the edges of the eyelet. A smooth final result is important, since even the smallest uneven edge can catch and break the fine wire used in pickup coils. If there is any excess brass, file it flush and smooth.Drilling the hole

Setting the eyelet with a hammer

Setting the eyelet with a press

Clean up any excess brass