You need a bag of clothespins for your workshop!

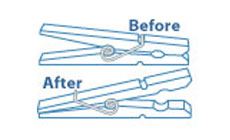

Today I used clothespins as kerfing clamps, and I was reminded of how many uses they have. I’m even using them as Christmas presents... Here are some of the ways I modify wood clothespins for use in my shop: Turn the spring around backwards, and the wooden jaws become tapered, light-duty clamps. They can hold parts when I’m soldering (first photo), or keep binding strips together when I’m about to glue them (second photo). ...for gluing new kerfed lining on an old Gibson archtop about to receive a new back. I customized this batch so they’ll grip kerfing tightly and they’ll last for years. I cut an angle into the jaws so they’d match the shape of kerfing. This meant cutting away some wood: the penciled area on the pin at left shows what had to be removed. One side got an angled cut to match the kerfing (roughly a 13° angle). The other side was just pared down to the depth of the curve that already existed in the jaw. I used a gauged saw and a chisel to cut these jaws into shape. I enjoy just sitting at my bench, working with hand tools for little jobs like this. It’s relaxing. Testing the first one I made, I found that the clothespin spring didn't have enough clamping strength. For more oomph, I wrapped the clamp with a rubber band. But the added pressure caused the wood to break at the thin point created by my angled cut. Shoot! Too much wood had been removed. Hmmm... I glued a reinforcing strip of wood on the backs of the wooden pieces using #20 super glue, zapping them with accelerator. Then I sanded the pieces smooth.This reinforcement did the trick: They’re strong enough to stand up to the added pressure of a rubber band. With Titebond, I glued several pieces to the edge of a pine board. Rubber binding bands held them together until the glue dried. After an hour of dry-time, I bandsawed the wood so each of the clothespin pieces came away with a strip of the supporting wood attached. I smoothed this long strip of clothespin halves on the belt sander, then did my jaw-shaping before cutting them all apart into separate pieces. These are really useful, and I know a luthier who would be happy to have a set. I made a double-batch so I can give the extras as a Christmas present. I wanted them to look nice, so I wiped the pieces with fretboard finishing oil. It dried in an hour, leaving a good-looking sheen. Hey, this is practical too: the finish will make it easier to clean glue from clamps. I think a couple bundles of these kerfing clamps will make a nice present! I like to use hot hide glue for gluing kerfing. But it does set up fast, so I need to move quickly. I’ve got maybe two minutes to get everything clamped up before the glue gels. To gain a little more clamping time, I warm the basswood kerfing on an oil-filled space heater. Keeping an eye on a surface thermometer, I get the wood as close to 100° as I can. I also turn the heat up in my shop when using hot glue. The glue itself is warmed in a small jar that’s suspended in heated water in my electric glue pot.Handy-dandy clamps! You need a bag of clothespins in your shop. Here’s why

Clothespins make great mini-clamps.

Today, I turned clothespins into kerfing clamps...

They were easy to make, and I had fun doing it.

Back to my clothespin clamp:

Mass-production time!

Why not put a finish on them?

Ho Ho Ho!

Check It Out!

I've said it before: I'm a hot glue fan