Banjo 5th Peg Drill Jig Instructions

How to locate and drill a 5th peg mounting hole for banjo.

The StewMac Banjo 5th Peg Drill Jig helps you locate and drill a perfect 5th peg mounting hole for a typical five-string banjo. The included 11/32" drill bit with depth stop ensures the perfect hole diameter and depth.

The banjo neck pictured in these instructions has no fretboard installed. This jig works equally well before or after installing the fretboard on the neck. Read through these steps before you begin, so you understand exactly where and how to drill.

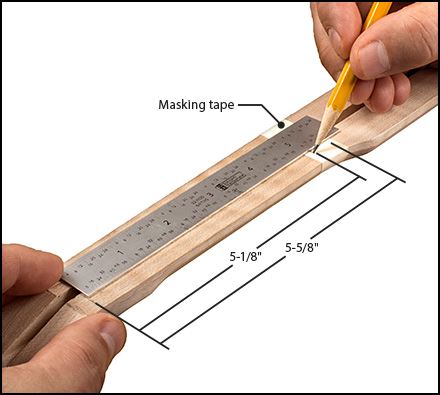

1. Mark two points on the surface of the neck

Measuring from the “zero point” of the fretboard, where the fretboard contacts the nut, draw a pencil line at 5-1/8" (130mm) from the nut. Make a second line at 5-5/8" (143mm) from the nut.

Wrap masking tape around the neck to avoid marking

directly on the wood.

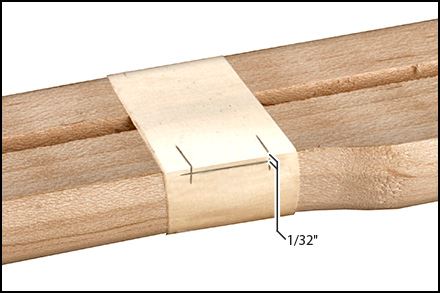

2. Transfer the two points onto the side of the neck

At each of the two points marked above, extend your line down onto the side of the neck. At each point, make a mark 1/32" (0.79mm) below where the fingerboard joins the neck. If no fingerboard is installed, as in our photos, your marks are 1/32" below the surface of the neck.

Draw a pencil line between these two points. This guideline marks the top of the hole that you will drill.

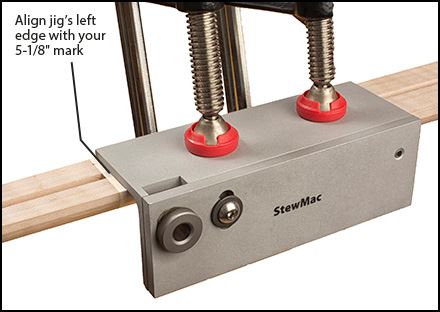

3. Clamp the jig in place

Align the edge of the drill jig with your 5-1/8" mark on the surface of the neck. Use two clamps to fasten the jig firmly in place. Avoid damaging the neck by using wood or other protective material between the clamps and the back of the neck.

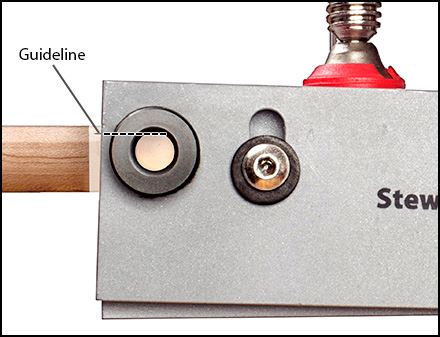

4. Align the drill bushing

Loosen the adjustment bolt so the pivot plate rotates. Sighting through the bushing, align the top of the bushing with the guideline you drew in Step 2. Tighten the adjusment bolt firmly.

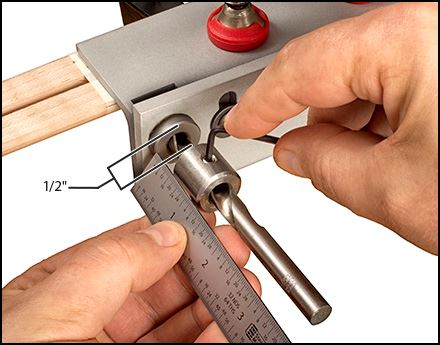

5. Set the drill depth

Insert the drill bit into the bushing until the tip touches the neck. Tighten the depth stop on the drill bit, leaving a 1/2" (12.7mm) gap between the depth stop and the bushing. This 1/2" gap is the depth of the hole to be drilled.

Mount the bit in your electric drill and insert it into the bushing.

6. Drill the peg hole

To drill a hole with clean edges (no tear-out), have the drill rotating at full speed before it contacts the wood. Push the drill in slowly until the depth stop contacts the bushing. Keep the drill rotating as you pull it back out.

You now have a properly located hole, ready to accept a 5th string peg.

7. Ream for larger 5th string pegs

Most styles of 5th string tuning pegs will press into the hole created by the 11/32" drill bit. If your 5th peg is larger, finish the hole with a tapered 5th peg reamer for a snug fit.