How to install a skin banjo head

Issue 286 June 01, 2017

How to install a skin banjo head: Dan Erlewine shows his friend Lauren how to remove and replace a natural skin head on this old banjo-uke, or banjolele.

- Check out this old Gretsch banjolele!

- Cutting the old head from the flesh hoop.

- Soaking, stretching the replacement head.

- Dan’s easy-to-make jig makes the job a lot simpler.

Video Transcription

[on-screen text reads: Installing a sking banjo head - StewMac]

Dan Erlewine: Here's my friend, Lauren Johnson, a singer and player in town here in Athens [on-screen text reads: Dan Erlewine Guitar Repairman, Author]. And she has just been gifted with a Gretsch banjolele from, I don't know, the 1920s or '30s it's in killer shape, but the skin head is ripped. A banjo skin in the old days is made out of calf skin. She came to me, wanting me to install the skin head on the banjo and then decided she'd really like to try it herself. So you do want to do it yourself?

Lauren Johnson: Absolutely. I think that sounds great. What do we do first?

Remove the old skin head

Dan Erlewine: I'll get you a wrench and you're going to take all these brackets off. You don't have to remove the nuts entirely [on-screen text reads: stewmac.com Bracket Hex Wrench], you can just loosen them enough then you'll be able to get that head off.

Lauren Johnson: I think that's enough.

Dan Erlewine: Yeah. You'll know when it start popping down. Take that little part off too, just while you're at it. You can use these lugs to pry against. You don't even need it.

Lauren Johnson: Oh, wow.

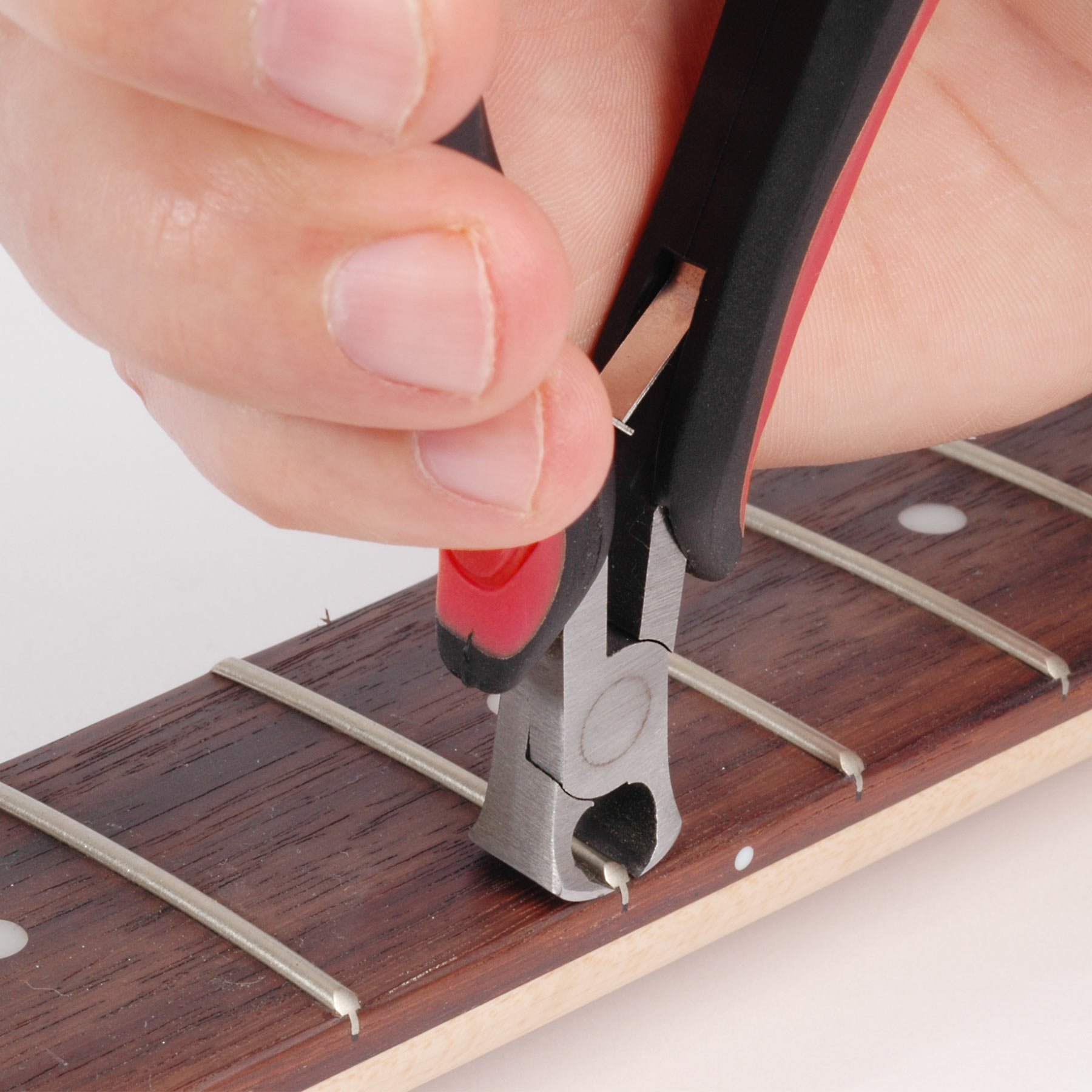

Dan Erlewine: Go all the way around. A little here and a little there. There you go. That's probably the original skin. Once it comes loose, you can use your fingers on it. Now it's easy, you can just back it right out. Sounds like a bird caller. That neck will come out of there. No it won't because look, there's a nail in there. We'll put a Feeler Gauge on it, release and go down and start again, because you're trying to keep that nail straight [on-screen text reads: stewmac.com Fret Puller].

Remove the neck

Lauren Johnson: All right. Nail's out. Yep. Now you can get the neck off.

Will this slide right out?

Dan Erlewine: Yep. Pretty easy.

Lauren Johnson: Not too bad.

Remove the skin head from the flesh hoop

Dan Erlewine: Here, we're taking off the old skin from what's called the flesh hoop. It's a ring of steel and we're going to save that because the new skin's going to wrap around it.

Lauren Johnson: I almost feel a little guilty cutting into something so old.

Dan Erlewine: You're doing it a favor. It peels right off. You want that clean so when that skin gets wrapped around it's not fighting it.

Lauren Johnson: All right. It's pretty shiny now. What do we do next, Dan?

Wax the flesh hoop

Dan Erlewine: We are going to wax that. You can wax it with some bees wax or paraffin. Do you want to do this just so it's slipperier because that skin's drying as you start putting it on, it starts to dry quick. And I would say let's wax that with some paste wax.

Prepare the new skin head

You're going to get white talcum powder on your hands. It's just to keep the skins dry on the shelf. It's way bigger than you need. This is for a bigger banjo. And even then it's pretty big. So you can just by eye, kind of lay it out. And then we'll make a circle and cut it. That's two, two and a half inches out there.

We're going to soak it in water for about a half an hour to make it pliable and keep it submerged. While we work on something else.

Install the new skin head

That made a little crude holding fixture to hold this thing, holding it in your lap would be really clumsy [on-screen text reads: stewmac.com Guitar Repair Vise]. And this isn't very fancy. It's a stick going through here, going through one of those portholes. This is going to hold this thing so we can work on it.

Take your little ring and try to get equal over hang. You want to line up this notch over that hole for the stick. Now start pulling this up.

Lauren Johnson: Okay. I see.

Dan Erlewine: And tuck, it takes a while. It's like making a cupcake or something. Now you want to tighten it. Get a hook like here, here, so you're balancing the pole all the way around. Right now while it's still wet, take a break and cut this off. Don't cut the head. You can't cut it very easily when it's all dry, leave a little peeking above. Good.

Lauren Johnson: That had me so nervous.

Dan Erlewine: Did it really?

Lauren Johnson: It really did. He was like, "don't touch the head." I was like, "oh God, that'd be a great way for the video to end."

Dan Erlewine: That sounds killer. And let it really dry and come back and check it out. Tada!

Lauren Johnson: Oh man. It's so cool. I'm so excited.

Dan Erlewine: It really is.

Lauren Johnson: Yep.

Reinstalling the neck and new tuners

Dan Erlewine: Let's put it together. It just takes a couple of snugs once you...

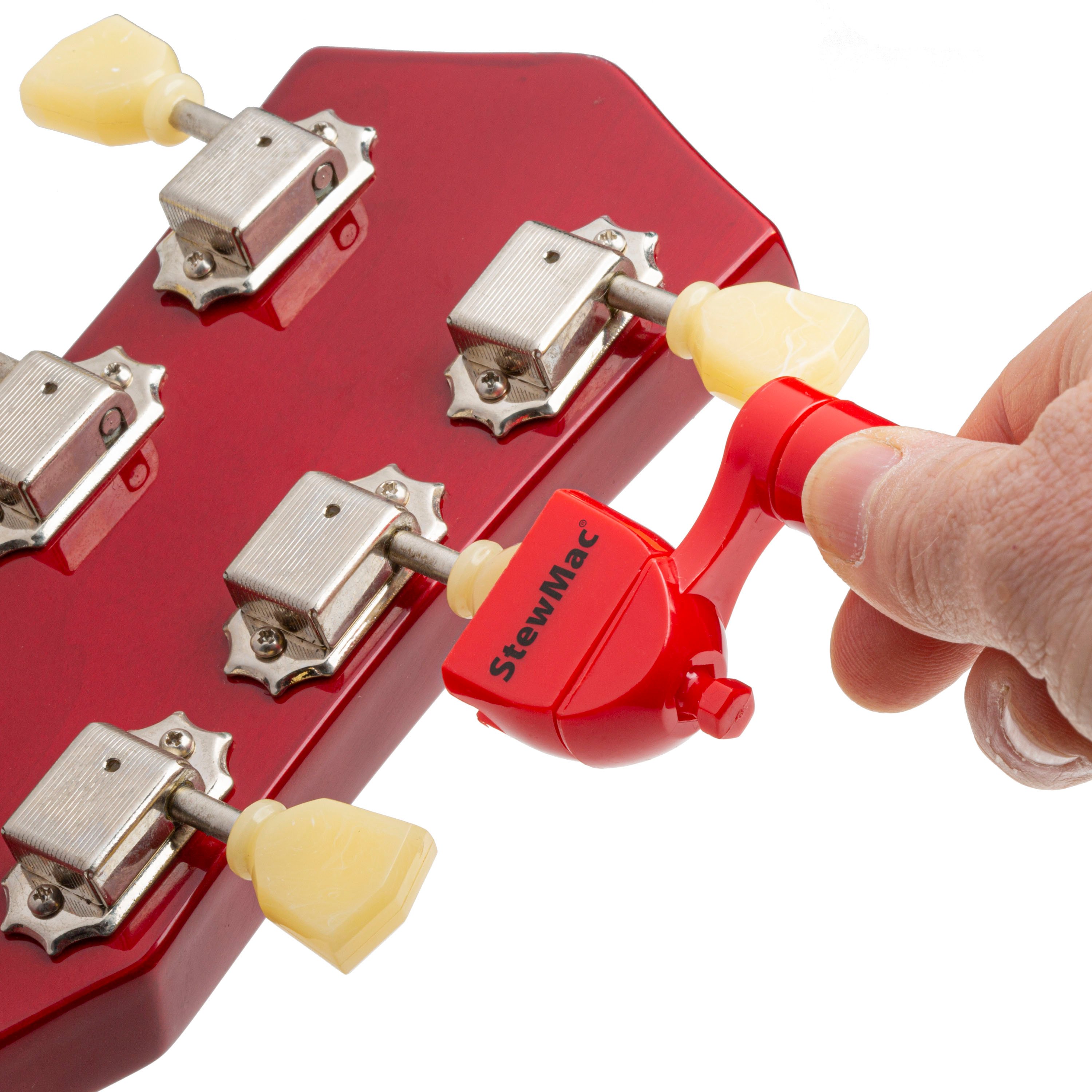

Now we can put strings on it, but really these tuners are not going to work anymore. That one's bent and the plastic's crumbling. So as a thank you present for working on this video, I present you with some Waverly Uke tuning machines.

Lauren Johnson: My goodness. Well thank you so much, Dan. Oh, a little sticker. Holy cow! These are beautiful [on-screen text reads: stewmac.com Waverly Ukulele Tuners]. Oh my word.

Dan Erlewine: It's coah.

Lauren Johnson: God, they're so pretty. You did good Dan.

Dan Erlewine: You did this.

Lauren Johnson: I mean, this is great pick. Look at that. It's a real banjo [on-screen text reads: stewmac.com StewMac Stringwinder].

Dan Erlewine: Wow. They'll go out of tune for a while. Because it's going to stretch here at the loop end. It's yours. Congratulations.

Lauren Johnson: Well, thank you very much. Wow. I wouldn't have been able to do it if you hadn't have shown me how.

Dan Erlewine: Maybe, but you can do it next time.

Lauren Johnson: Next time.

Dan Erlewine: I got one coming in, you're hired.

Lauren Johnson: Sounds great. I'll be here.

Dan Erlewine: Take it away Lauren. First try. Sounds good, so far.

Speaker 3: (singing)

Dan Erlewine: (singing)

Speaker 3: That's really great guys.