Guitar repair using kitchen chemicals

Issue 293 September 06, 2017

Trade Secrets visits RetroFret Vintage Instruments in New York to talk guitars — and groceries. Steve Uhrik, RetroFret’s owner, shares tips for using chemicals you’ll find in your kitchen cabinet!

- White vinegar!

- Meat tenderizer!

- Sodium Bisulfite!

- Eggs? Milk?

Video Transcription

[on-screen text reads: Dan Erlewine - Guitar Repairman, Author]

Dan Erlewine: I visited Steve Uhrik, an old friend of mine and great repair man who owns RetroFret in Brooklyn, New York. It's loaded with every kind of guitar you can imagine from acoustic to electric and has a fine repair shop. And Steve started out by showing us how to use kitchen chemicals for repair work. There were some other tips in there too.

White vinegar

Steve Uhrik: Hi, I'm Steve Uhrik. Owner of RetroFret Vintage Guitars, here in the repair shop, and I'm going to talk about food products today that we use to repair guitars. Something I've used for many years is just your white vinegar. Get it at your local Krasdale department store or anywhere else.

It basically stops chemical reactions. These days when we're doing more intricate repairs, if there's a piece of wood that we're going to splice into a guitar and we want to lighten it up to try to match tone with a stain or something like that [on-screen text reads: Without vinegar, bleach can keep lightening even after you apply stain]. We'll also bleach it so we can control it better. But again, has to be neutralized, otherwise you end up with a mess after you've stained it.

Sodium bisulfite

Another food preservative product, sodium bisulfite, and I'll read this here. It says it's good for vegetables and fruits and it's used if you're a canner and you like to can your vegetables and fruits. It's an antioxidant, so it makes it last longer. I'm sure a lot of you have seen pickguards. Oh, come in.

Dan Erlewine: Cut.

Steve Uhrik: So in terms of what we need to preserve in terms of guitar repair, I'm sure a lot of you have seen celluloid nitrate pickguards that have gassed off or really oxidized, very volatile materials like movie film, it's very flammable, so you have to be careful how you handle it. Basically, it's slowly burning away. In this case, we have a hole that has developed there and will keep spreading, will keep oxidizing until you end up with a bag of dust, essentially.

A lot of people will just try to fill it with some material, but if you're not going to stop the chemical oxidation process, then you're still going to have it leeching out from that point and continuing to deteriorate. So what we do is actually take just a regular two-part epoxy, of course, we'll usually tint it with something, very often an aniline or an earth tone, and we'll add a couple of pinches of sodium bisulfite to it.

And that in many, many cases has helped to stop the pickguard deterioration from spreading.

Meat tenderizer

My real favorite trick, and I would like to give credit to Joe Pecnik for many of these tricks, he was the head technician at the Metropolitan Museum of Art for many years. I'm sure anyone who's done a neck set who had particularly gnarly time with a glue joint where it's a very solid, deep pocket glue joint, when we steam it, we add meat tenderizer.

Meat tenderizer is an enzyme that breaks down protein and most glues have some type of protein bond in them. Certainly any type of hide glue would, rapid glue, hot hide glue, if you mix that in your water, or water that you're going to use for steam, it really takes the glue joint apart. I used to use alcohol on occasion for that, but this really does the trick. And we do have a barbecue on the roof. I should mention since we're on film that you can buy official RetroFret meat tenderizer that will tenderize your glue. It's only $20 a bottle. We wanted to get in there before StewMac scooped us on this, so operators will be standing by.

Marking the Brace Repair Jack with super glue

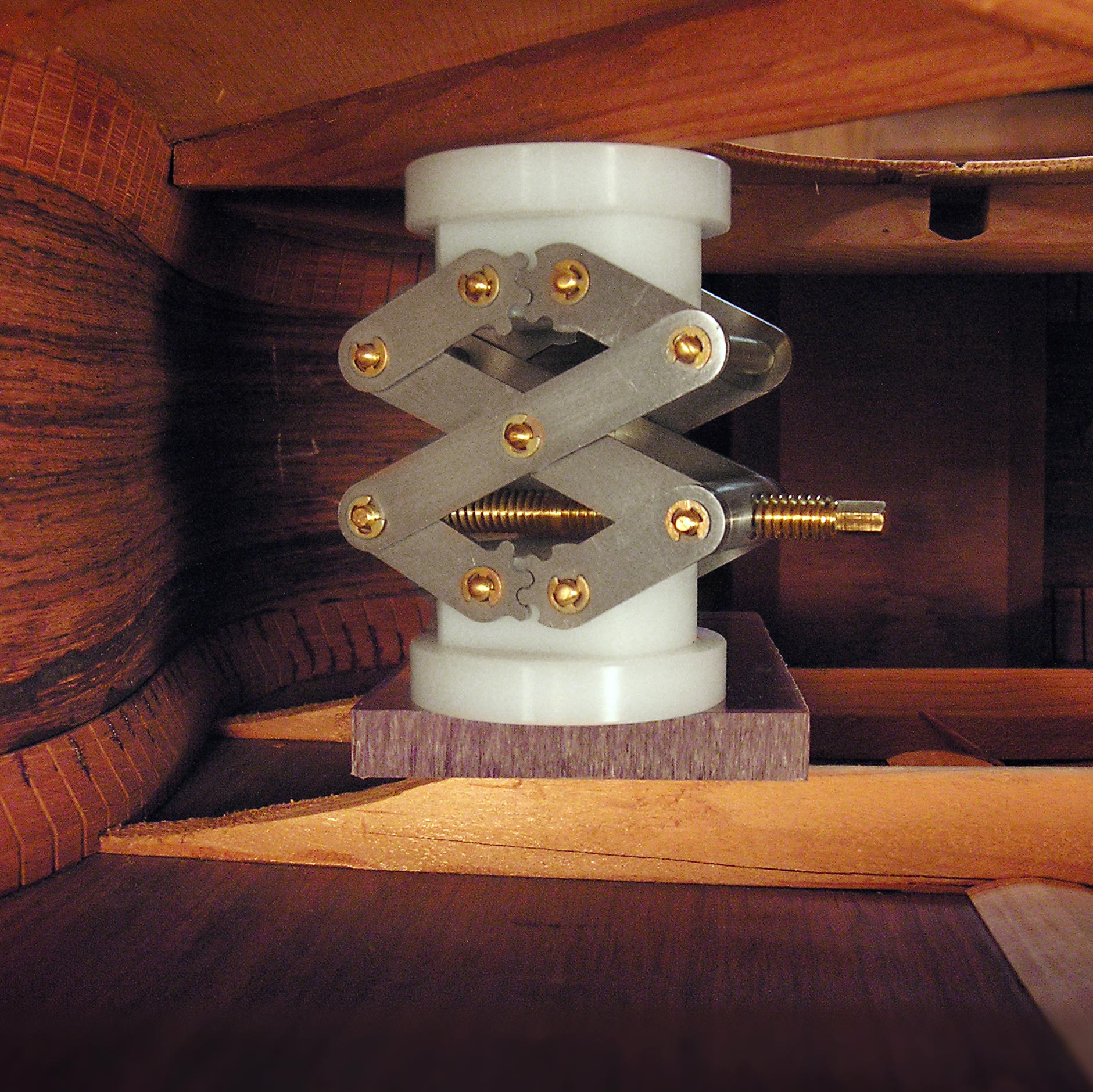

Harry Bolles: Hi, I'm Harry Bolles, I'm a Repairman here at RetroFret Guitars in New York. I just want to show you a couple things that I've been doing with this barrel clamp [on-screen text reads: StewMac Brace Repair Jack - stewmac.com]. First of all, I'm often not able to see what I'm doing once I'm inside a guitar. So I've marked one side of it with just two big dots of super glue and that way when I drop it in, it rolls around, which I inevitably do, I can pick it up and I know which way I'm turning it without looking. And that saves me a little bit of time.

Tricks for setting and using the Brace Repair Jack

Then after a long night of reaching around inside an F-hole guitar, I came up with this, which is a wire with a little handle on it that just clips right on. It's stiff enough to clip on. I can just squeeze it close there, and that way I can reach inside a sound hole or an F hole and get it right on there. And then once I have it there, what I did was take one of these pencil sanders, and just take the belt right off. Old belt, flip it inside out, and used it as a drive belt here.

So fit that, fit that, try not to look. It'll turn pretty well. I can get a huge amount of torque by just turning that and then I can just leave it alone and then do it backwards to get it out the next day.

Dan Erlewine: Thanks, Harry. That's a good tip. Of course, I went home and tried it, but today we have a newer version, the new improved version [on-screen text reads: StewMac Brace Repair Jack - stewmac.com], which instead of having a rubber sleeve, has a knurled brass, which we find easier to grip with your fingers. With the sand belt, I wasn't quite able to get the grip that you could because you were working on rubber. But with a rubber binding band, I could do it just like you did. It works great. Thank you, Steve, and all your crew. Had a great day there at RetroFret and hope to come back next year.