Thompson Belly Reducer Video

V-1380

Dan Erlewine demonstrates the Thompson Belly Reducer and TJ Thompson explains why he created this clever system to begin with.

Video Transcription

[on-screen text reads: Stewart-MacDonald - Thompson Belly Reducer]

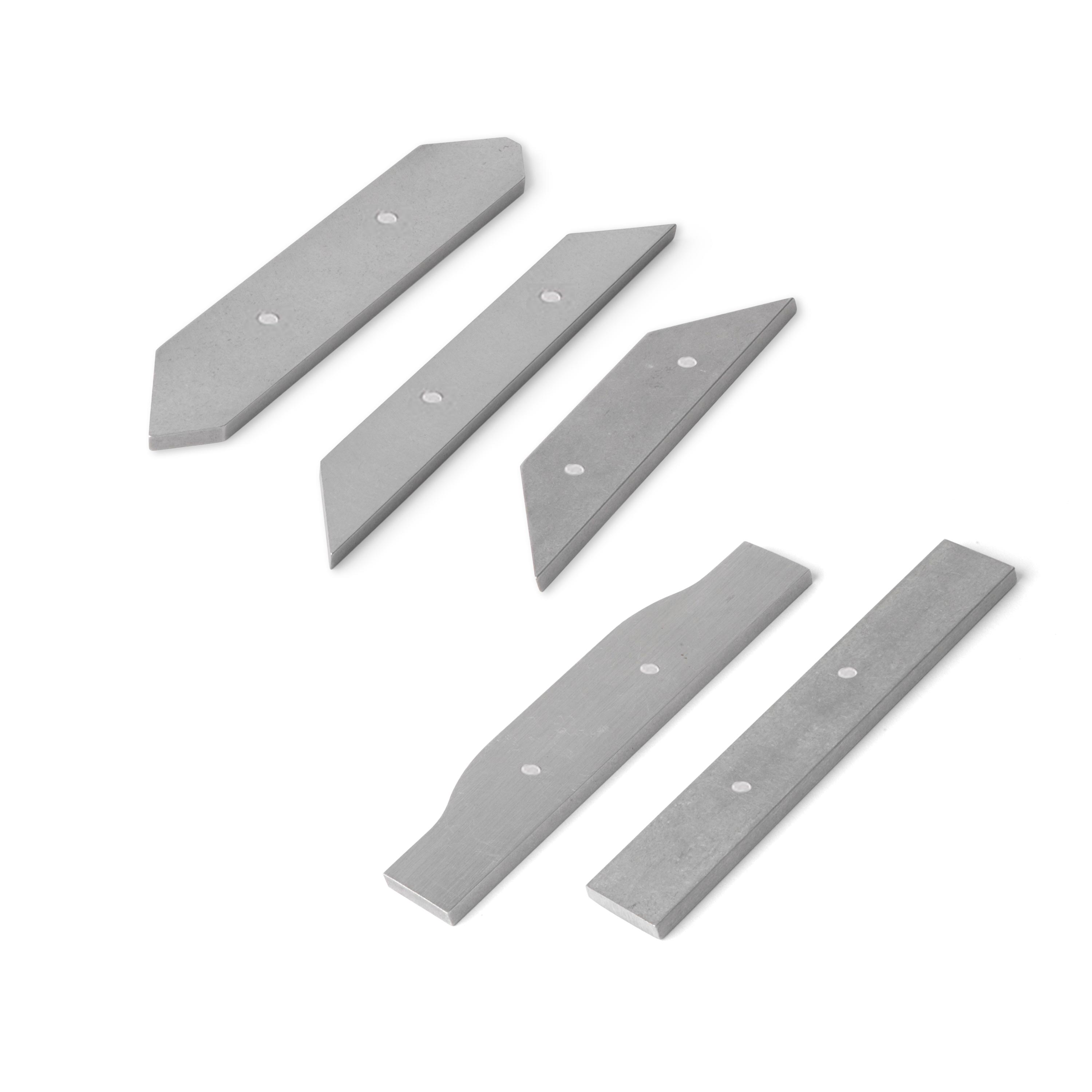

Dan Erlewine: Here's an old vintage guitar, a 1941 Martin 00-17 that I just flattened the top on. It had really warped up over the years from string tension, and developed the kink, the famous belly, the belly top. The fix for that is the TJ Thompson Belly Reducer. A set of machined aluminum cauls for flattening out a top. The caul that goes on the inside has a convex cavity, the caul that goes on the outside where the bridge would be, is concave. Together they mate and push the top down and flatten it out.

You heat the calls and then clamp them in place with bridge clamps and that's where these magnets are so helpful as you place the clamps through the sound hole. The video you're about to watch was made before we added the magnets, so bear that in mind.

This is a 1941, 0-17 Martin here and look at the belly on that thing. It's warped from years of playing and heavy strings, and it won't hold a bridge. With the belly reducer, I can flatten this out and it will have a new life. I ran into TJ at the trade show recently, and here's how he describes this tool.

Why was this tool invented?

TJ Thompson: I knew I had to do something when vintage guitar prices started skyrocketing because one of the first questions that a dealer will ask you is has the bridge plate been replaced? Not that long ago, you could buy 0M-18's for $3,500 all day long, and now they're about $35,000. I didn't want to be the guy who had replaced the bridge plate lowering the value by about $3,500. Now the bridge plate itself, just changing it, can reduce the value that the guitar used to cost. You could buy the whole guitar for that. I said, all right, enough, I got to do something. I designed this tool that when the bridge is off, you put an insert on the inside and a mate for the top, clamp them together under heated pressure, and it flattens the top back out so you don't have to take the bridge plate out and replace it.

How the Belly Reducer works

Dan Erlewine: I can tell you it's a great tool and let me show you how it works. The cauls are curved, so they bend the wood, counteracting the belly curve. A set of matched calls are heated and clamped to the belly area. The effect of the reducer is enough to lower the action and give a fine guitar a new life without replacing the bridge pad. It's really nice when you can fix a bridge plate, not replace it.

Choose the right bridge and bridge plate tools based on the footprint of the bridge and the size and shape of the bridge plate. Heat the two parts to 150 degrees, immersing them in the water of a hide glue pot works perfectly. Dampen the exposed wood of the bridge area on the top and inside on the bridge plate with warm water using a sponge or a paper towel. Hold the plate flattening tool on the bridge plate with concave side facing up. Place the bridge template on top, convex side down. Insert a bridge clamp through the sound hole and clamp the two parts together, maintaining alignment of both tool parts. Finish by adding two more clamps through the sound hole spaced evenly. Tightened all the clamps as much as possible. You want to leave that clamped overnight or as long as you have time for and look at this, when I took off the clamps, it's flat enough to hold a bridge for another 30 years.