Making a Guitar Nut: 3 Tips for Proper Slotting

V-1320

Making a new guitar nut? In this video Dan shows 3 tips for getting the job done right. Getting the proper shape, ramping (or backfiling) to ensure proper intonation, and opening the back of the nut slots to get an unobstructed path for the strings.

Video Transcription

Dan Erlewine: Today we're working on the guitar nut and making a nut for the Gibson J200, and I want to point out a few things about making a nut while I'm doing it.

Getting the right width and slot depth

It's very important of course, that you get the strings spaced properly across the width of the nut and to the right depth, not too low. Where it would buzz on the fret, not too high where it would be just too hard to play. You want the string to take off at the front of the slot of the nut and meet at a peak like the saddle. These two points control whether the intonation will be proper. To ensure that you get that, you need to do as much work on the backside of that nut as you do at the front, and that's what we're going to talk about today.

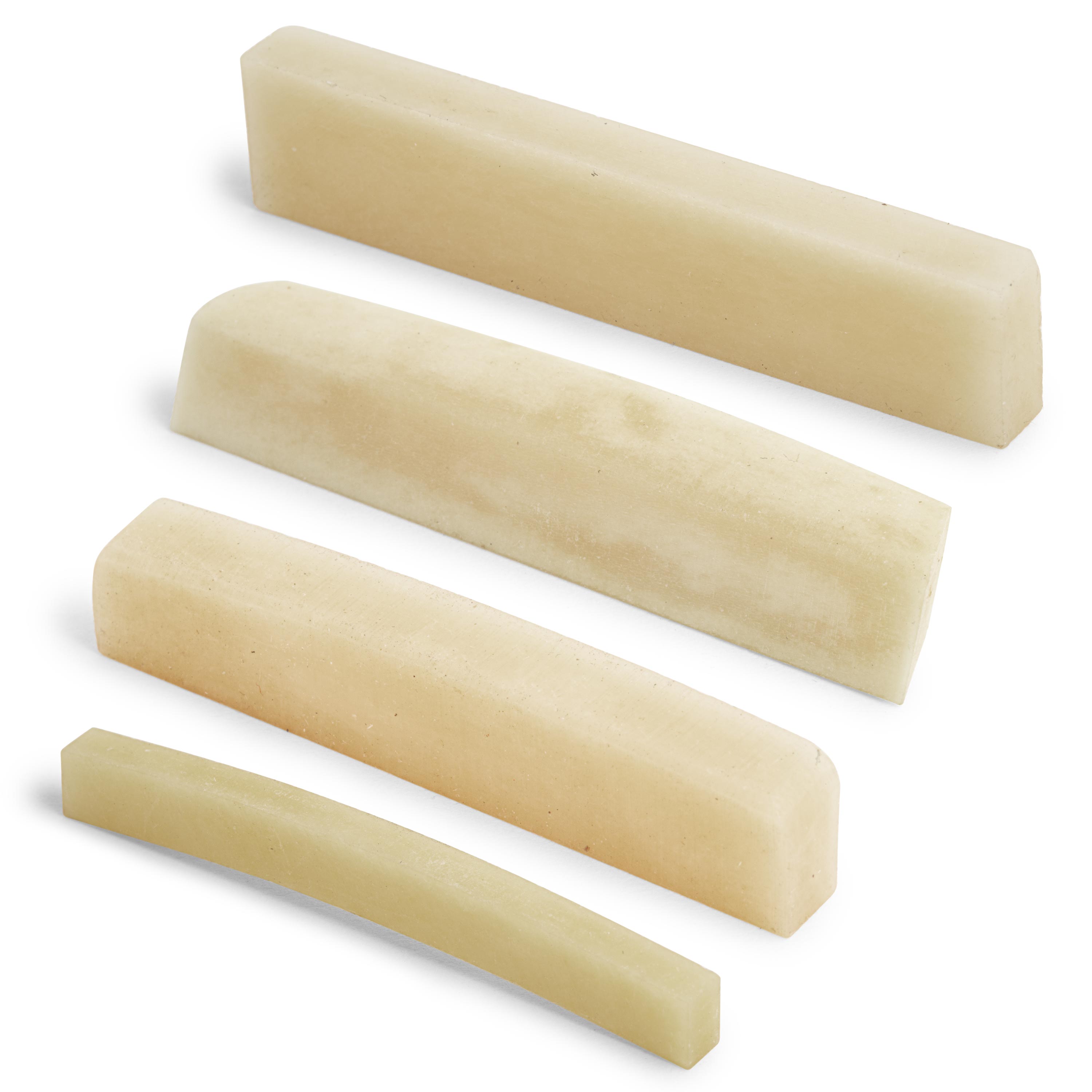

The first thing when making a nut is to round it so the back slopes downward like this. I grab three nut blanks off the shelf. These are pre shaped and pre slotted. This is a Martin. It's the widest. It gives the most meat to round off. Here's the Gibson, at least the way it starts out, it's rounded but not in such a steep fashion. Any hard edges are rounded off. Then the fender, they don't have a lot of width to do any rounding, but they do put it in an angle. The slight back angle, that's the angle you're going to be filing at anyway.

When you're making a nut from scratch, starting with the blank, there's three things to think about when you're cutting those slots. One important thing first would be the right depth. The second thing is what goes on behind the string on the backside of the nut. It has to be backfiled downward at a gentle angle towards the tuning keys, so that the string is free to take off at the front of the nut.

Backfiling the backside of the nut downward at a gentle angle

In this picture, the slots might be at the right depth, but they're just flat straight across. That's not what you want. There's no takeoff point at the front. The string must gradually be backfiled, going downhill towards the back of the nut, but not a sharp angle like this. There's no meat to support to take off that would wear out in days. To get the right shape. We round the slot in a gradual slope like this, it leaves a lot of material to support the string, guaranteeing that it will vibrate from the front of the nut and still have enough material to prevent it from wearing down too fast.

Opening up the back edges of the nut slots

The third thing, which is pretty much the point of this lesson on the backside of the nut, when the string's coming through that sharp slot, you want to open the back edges of the slot up. It's like coming down a mountain into a valley. You don't want to kink when that G string and D string comes off the sharp bone nut, you want to help it head towards its tuner.

Okay, now we're going to see how to do this job. It's not going to take a long time. It's a subtle thing, not a big thing. I have got the string height in this nut right where I want it. I've also taken all the extra meat off the top of this nut, because it started out as a blank and I worked my way down. Now each string is sitting in about half of its diameter in the slot. That's plenty to hold it. One at a time. I'm going to go through this and open them up. Give them the valley.

I'm going to start with the D string because it's easy to see. It's a good demo there. It's also one of the slots that has the most kink to a string. See how it comes out and it's a little kinked. I'm going to move that over a little bit. Open up that valley, so to speak. I'm going to put a little pencil on that. I'm sliding this low tack tape underneath the strings just for a little protection. Today I'm going to use a new file that I'm raving about. They're killer. These are diamond plated nut files [on-screen text reads: DiamondCut Nut Slotting Files - stewmac.com]. What I love about these files, they round on the bottom, really smoothly plated with this diamond. It's not like having a tooth file. A tooth file can skid, especially like on a tune-o-matic Gibson bridge with the chrome plated saddle and you have to cut the notch and it slips off. These don't, because they don't have teeth to run you off. Going to just kiss this little valley that I'm going to go for.

It's almost like you're imagining the string flowing to that side and you leave it. I've opened this up here a little bit, just opened it up. Leans a little bit towards that side to make sure there's no burs on it. It's hard to see it. Once you clean it and sand it up, you'll see it easier. Now the string is going to tend to not have a big kink as it goes over gentle little curve. You can see it. You don't need hardly anything on the A string, on the low E, not much. It's just that clean up. G string. Just a little bit on the downside. That careful slanting of this to just the right spot, I think is responsible for good intonation and good sound.

Now any of that little black pencil dust will clean up. When I knock this down to shape, the back edge is going to get rounded more and polished. That's it. It's just a little bit of knowledge that you might not have had. Just the little thing. It's all the little things that add up to have that ramp or valley and open up that string so it can speak. It's worth it. That's part of making a nut. If you like these how-to videos, would like to help us keep them coming. Subscribe to our YouTube channel.