Why Dan Erlewine is attracted to repair magnets

I started using magnets for some unusual guitar repairs. Pretty soon they became everyday repair tools. This morning I noticed that they’re everywhere in my shop — I’m hooked! Look at some of the problems they solve: On this cutaway guitar, see how a 1" repair magnet on the outside controls a piece of sandpaper on the inside. The inside magnet is faced with 80-grit self-adhesive sandpaper, and it follows wherever you move the outer magnet. This setup powders away glue residue beside braces and anyplace you find it hard to reach with your hand. The outside magnet is padded with a scrap of smooth leather, so you can slide it back and forth while the inside magnet does the work. Can you reach this far inside a guitar to spot-sand any other way? Instead of sanding, bundle the inside magnet in damp cloth to clean up Titebond glue squeeze-out when you glue braces. Magnets embedded in wood or plastic cauls become clamps that pull together even though they’re not attached. Use an inside/outside pair to put the squeeze on a crack where no clamp could reach. Or as a third hand to hold a bridge caul in place while you set up your soundhole clamps. Two magnets stacked together increases their clamping strength a bunch, and stacking up three or four makes them even stronger. A chunk of steel or iron stuck to them (like the thread cutting die shown here) makes the stack even stronger. Try different combinations to see how much clamping pressure you need. The stack you see here packs a wallop — three magnets on one side, plus the steel die, and another magnet on the other side with a chunk of steel stuck on. That may be more magnetism than you want to tangle with! Check out this video on stewmac.com Dan Erlewine demonstrates the Mini Cam Clamp — his lighter, skinnier version of the traditional cam clamp. See how less bulk means more clamps will fit in tight spots like this one. My repair vise is the target for a lot of magnets. How about this: nut-slotting files right where I need them. I’m working on a Gretsch White Falcon, moving from one gauged file to the next without even turning away from the work. On the base of the vise, I have one magnet to hold the guitar tech screwdriver set with all its bits in one handy spot. For finish touchups with stains, magnets hold my “artist’s palette” (a plastic lid from the kitchen). I hold mixing cups of lacquer thinner by dropping a small magnet in them. A: Yes. It's always easy to find these tools. My drill chuck key never gets lost because I hang it on a magnet, and my hack saw has a magnet screwed to its handle. (Those holes in the magnets are handy.) You’ll like this when you try to pull these super-strong magnets apart. I made a wooden handle with a short brass peg in it. The brass won't stick to a magnet, but it will hook the magnet’s center hole allowing you to pull it sideways off its mate. I epoxied these two magnets to the jaws of a nut and saddle vise. This rig will charge the polepieces in a just-wound pickup — or change the pickup's polarity depending upon which way you run it between the magnets.Why I'm attracted to repair magnets

Doing the impossible: SANDING

Sanding impossible spots

Doing the impossible: CLEANUP

Cleaning impossible spots

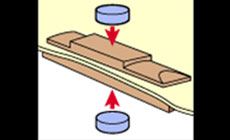

Doing the impossible: CLAMPING

Clamping impossible spots

Power tip:

When clamps go on a diet...

Magnets around the shop:

Q: Can you find the tool in this picture?

One last tip:

Wait! I’ve got one more!